Function

In addition to adding sweetness, brown rice syrup gives baked goods:

- Moist cake and bread crumb

- Food for yeast

- Desirable flavor

- Crumb and crust coloring

- Shelf‐life extension

- Masking of beany flavors in formulations rich in soy

Composition

Similar to other syrups produced from starch hydrolysis, rice syrup contains a mix of glucose, maltose, and higher saccharides. The following table summarizes its composition:1,2

| Component | % |

| Water | 18.0–20.0 |

| Glucose | 3.0–5.0* |

| Maltose | 45.0–65.0* |

| Water soluble complex carbohydrates (higher saccharides)** | 50.0–30.0 |

| °Brix” | Min. 78 |

*Make up 100% of total carbohydrates

**Comprised of maltotriose and dextrins (usually less than 10 glucose units in length)

Nutrition

In the U.S., this syrup is usually found in the “healthy food” section of grocery stores. It is considered a healthier option than other sweeteners, like high DE glucose syrups, or pure forms of sucrose and fructose.

Commercial production

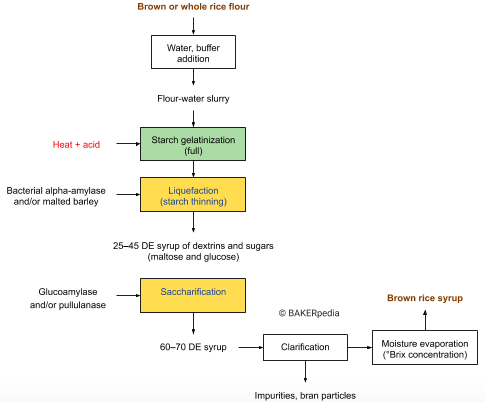

By definition, this ingredient is considered a low-conversion glucose product since it ranges from 26 to 70 DE (dextrose equivalent). It is made by enzymatic hydrolysis, using processes similar to those normally found in making corn or glucose syrups.2,3 It is usually sold in the U.S. with the USDA Organic certification. And since it comes from whole rice, it retains some of the vitamins and minerals from the rice caryopsis.1

The following diagram shows the production process for this ingredient:

Application

Totally or partially replacing sugar with brown rice syrup is possible. However, it’s not necessarily at a 1:1 ratio. It is mostly sold as a low DE sweetener, which means it’s less sweet and has a lower amount of fermentable solids than regular sucrose and corn syrups.

Due to its water content, brown rice syrup calls for a reduction in dough water absorption when partially or totally replacing sucrose.

Brown rice syrup cannot help cream cake batters, so formulas have to be adjusted. It is also important to have in mind that brown rice syrup is less sweet than table sugar, honey, glucose and high fructose corn syrup.

The following table summarizes some features of this syrup versus other sweeteners:

| Brown rice syrup | 92–95 DE glucose syrup / 42 HFCS | Table sugar (granulated sucrose) | |

| Browning power | Medium | High | High |

| Fermentability | Low to medium | High | High |

| Humectancy | Medium | High | – |

| Hygroscopicity (competition for water) | Medium | High | High |

| Osmotic control on fermentation | Medium | High | High |

| Sweetness | Low to medium | High | High |

| Viscosity (ease for handling) | High | Medium | – |

| Creaming power (batter cakes) | Very low | Very low | High |

| Compatibility with clean label, organic/natural trends | Compatible | Not compatible | Compatible |

FDA regulation

There is no Standard of Identity set by the FDA for brown rice syrup.

References

- Figoni, P. “Sugar and Other Sweeteners.” How Baking Works. Exploring the Fundamentals of Baking Science, 3rd Edition, John Wiley & Sons, Inc., 2011, pp. 164–212.

- Wilkinson, H.C., and Champagne, E.T. “Value-Added Rice Products.” Rice Chemistry and Technology, 3rd Edition, American Association of Cereal Chemists, Inc., 2004, pp. 473–480.

- Mathewson, P.R. “Other Applications.” Enzymes, Eagan Press Handbook Series, AACC International, Inc., 1998, pp. 73–75.