How does it work?

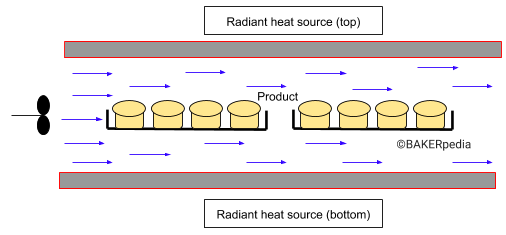

Heating products in a convection oven is done by a combination of the following heat transfer mechanisms:2,3

- Radiation from a heat sources such as electric resistances, vapor or hot gas tubes, gas-fired burner flames. This readily delivers heat to air and products.

- Forced convection from hot air, with fans generating air currents. Convection is the predominant heat transfer mechanism.

- Conduction from hot surfaces in direct contact with the product (e.g. racks or pans).

Convection ovens rely heavily on convection air currents and less on radiant heat sources. Therefore, the convective flow of air enhances the drying component of baking. This removes the fine water layer from the surface of dough/batter acting as a barrier (insulation) for heat penetration.

Dough moisture typically evaporates faster in convection ovens. As a consequence, the product bakes more quickly and more uniformly than conventional ovens. This reduces the total baking time.

Conventional ovens vs. convection ovens

In conventional ovens, heat rises to the top. So, items placed on the top rack bake much faster than ones placed on the bottom. While in convection units, hot air swirls all around the product. Therefore, adjustments in oven settings are necessary when switching from conventional to convection ovens.

For example, to maintain equivalent baking treatment at a constant baking time, temperatures should be reduced by 25–50°F (14–28°C). If no adjustments in oven temperature are made, then the bake time should be decreased accordingly to obtain equivalent baking treatment. Usually, it’s about 20% less.4

Application

In convection ovens, hot air is circulated by a fan at an air flow/velocity of 2–22 mph (1–10 m/s). This rate must be carefully set depending on the product and baking conditions. The convective heat transfer coefficient (h) developed during baking depends on the air velocity and temperature inside baking chamber. It can range from 20–120 W/m2 K.4

Fast air currents can distort the shape of delicate products such as sponge cakes, batters and soft doughs such as pastry. They can also dry out the products, negatively impacting their texture, shelf-life and overall quality. Rapid surface drying of dough pieces may form a hard skin which can prevent dough piece expansion during oven spring. On the other hand, too slow air currents can reduce the rate of heat transfer and increase the baking time. This hinders convection.

Ideal bakery products for convection ovens

While convection ovens are very versatile and can handle both yeasted doughs and deposited batters, these are not as beneficial for products baked inside high-sided pans that do not allow for a full contact between air currents and product’s external surfaces. Ideally, they would be used for free-standing products baked on sheet pans or perforated racks.

References

- Zhou, W., and Therdthai, N. “Heat and Mass Transfer during Baking of Sweet Goods.” Food Engineering Aspects of Baking Sweet Goods, CRC Press, Taylor & Francis Group, LLC, 2008, pp. 173–176.

- Fellows, P.J. “Baking and Roasting.” Food Processing Technology: Principles and Practice, 4th edition, Woodhead Publishing, Elsevier Ltd., 2017, pp. 733–749.

- Davidson, I. “Heat Transfer.” Biscuit Baking Technology: Processing and Engineering Manual, 2nd edition, Academic Press, Elsevier Ltd., 2016, pp. 59–70.

- Saravacos, G., and Kostaropoulos, A.E. “Heat Transfer Equipment.” Handbook of Food Processing Equipment, 2nd edition, Springer International Publishing Switzerland, 2016, pp. 315–318.