Function

This type of yeast, like other yeast forms, is essential for the production of fermented baked goods. It is responsible for the expansion of dough through the production of CO2, alcohol and organic compounds which characterize the texture, volume and flavor of bread and buns.

Viability and vitality of creamed yeast

Differences in yeast performance are evident when switching from dry to creamed. This is particularly true in high-speed bread and bun production scenarios. These require the highest level of product consistency when dealing with large quantities of dough.

Creamed yeast has superior viability and vitality compared to other yeast forms due to its lighter production process and high water content. Viability is defined as the percentage of live cells within a yeast population. Vitality is related to yeast activity or fermentation performance such as gassing power, sugar uptake or the formation of heat, CO2 or ethanol.

Conversion from one type of yeast to another is typically based on yeast solids content. However, when bakers switch to creamed yeast, they often see an increase in product volume and experience higher fermentation rates during proofing.

Commercial production

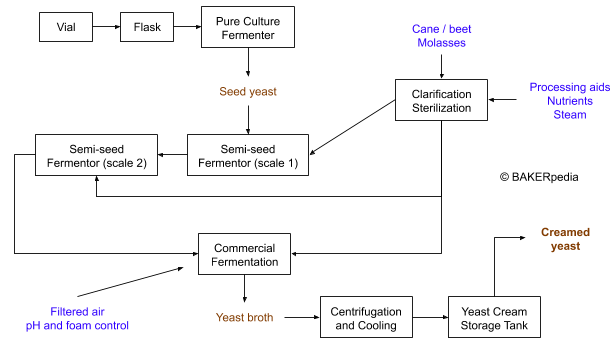

This block diagram shows the production process:

Post-large-scale fermentation in a dedicated bioreactor, yeast cells are harvested by centrifugation followed by repeated washing to remove residues of the growth medium.2

During this process, yeast cells are concentrated into a creamy pumpable liquid of standardized activity known as “creamed yeast.” The finished product is then transferred into refrigerated storage tanks and held at approximately 40°F (4°C) and is shipped to the bakery in insulated tank trucks.

Application

Upon arrival, creamed yeast is stored in a sanitized, refrigerated tank or silo. After emptying the tank, the system is cleaned and sanitized using CIP (cleaning-in-place) systems.

- Cream yeast offers many advantages including:

- High activity with fewer variations in performance

- Less opportunity for temperature abuse

- Ease of handling

- Accurate scaling

- No need for bags or boxes

The use of cream yeast is only economical for high volume plants because of the high cost of the holding equipment.

When is it a good time to switch to creamed yeast?

- Large daily production volumes. Bakers should consider using creamed yeast for continuous high production speed and processing line operating at 100 pieces of dough per minute or more.

- Compressed yeast consumption surpasses 20,000 pounds per week.

- Labor health and safety becomes an issue when handling sacks of compressed yeast.

- Manual operations in the production process need to be optimized and transport times must be reduced.

- Engineering and hygienic design policies demand a fully closed system for sensitive ingredients.

General recommendations when using creamed yeast

- This yeast has a shelf-life of 6 to 10 days. So, it must be stored under refrigeration and agitation. It should be treated in the same manner as compressed yeast.

- Shipping weight of cream yeast is about 1.70 times that of an equivalent amount of compressed yeast. 1 gallon of this yeast replaces approximately 5 pounds of compressed yeast.

- Flour water hydration must be reduced when using creamed yeast due to the creamed yeast high water content. Bakers need to make proper formula adjustments to avoid development of sticky or over-fermented doughs during makeup and proofing.

FDA regulation

There are no limitations regarding the use of yeast in the production of food products. Any type of yeast must conform to microbiological and physicochemical specifications established by the good manufacturing practices.

References

- Poitrenaud, B. “Baker’s Yeast.” Handbook of Food and Beverage Fermentation Technology, Marcel Dekker, Inc., 2004, pp. 712–735.

- Athnasios, A.K., and Quantz, M. “Yeast.” Ullmann’s Food and Feed, volume 2, Wiley-VCH Verlag GmbH & Co., 2017, pp. 1014–1026.