Why is the distinction relevant?

Direct gas fired oven:

- DGF ovens play a key role in the biscuit- and pizza-making industry. They are especially suitable for baking products that require high temperatures, often above 300°C (572°F) (pizza, flatbread, and other similar products). These ovens may also be used for baking all types of crackers, cookies, and biscuits.

- It is important to note that direct gas-fired and electric-fired ovens both have similar operation and heat transfer mechanisms.

Indirect-fired oven:

- IGF ovens are suitable for application in all types of products (especially baked goods of small dimension). Soda crackers are a notable exception, since these require direct heating in the early stages of baking.3

- Some bakeries prefer this type of oven due to its balanced treatment of products.

How do they work?

Direct gas fired oven:

- In order to directly transfer heat to the products, direct gas fired ovens use ribbon burners that are placed above and below conveyor belts, or bands in continuous ovens, or at the base of the cabinet in batch ovens. The flames created by each burner then radiate energy into the baking chamber, heating the air and the products.2

- Each burner is supplied with a mixture of gas and air. The pressure of this mixture (flow rate of each component) determines the extent of the combustion reaction (power delivered), and hence the temperature set point of the oven.

- There are various arrangements for adjusting the size of the flame across the width of the oven to ensure even heating across the band.1

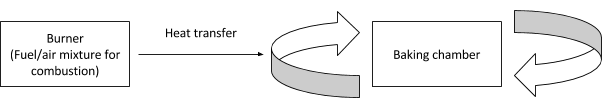

Block diagram for a DGF oven.

Indirect gas fired oven:

- The IGF oven makes use of the heat exchanger concept to transfer energy from burners to the products. The baking chamber is indirectly heated from above and below by the thermal radiation generated by high-temperature rows of steel tubes/ducts (exchangers).

- The tubes/ducts, which run the length of the oven, are first heated by hot air and combustion gases flowing inside of them. The air is supplied cool by a centrifugal fan (blower), and is heated by the burner to the desired temperature.3

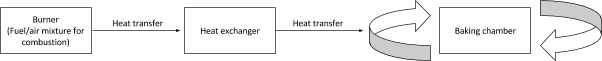

Block diagram for an IGF oven.

Main features

Direct gas fired oven:

- Allows rapid start-up, as it is only necessary to heat the air in the oven

- Permits short baking times (which lower energy consumption and operating costs)

- Has high thermal efficiency (high conversion of dissipated energy to heat the product)

- Enables good control over baking temperature

Indirect gas fired oven:

- Has slow to medium start-up time, as it takes longer to heat the air in the oven (heat must travel first and dissipate along the exchanger materials)

- Requires medium to long baking times (which increase energy consumption and operating costs)

- Has low thermal efficiency (low conversion of dissipated energy to heat the product)2

Equipment and maintenance

Direct gas fired oven:

- The insulation material of DFOs mostly consists of thick mineral wool slabs, resistant up to 700°C. Insulation thickness can be up to 40 cm to minimize the loss of heat to the surroundings.2

- Overhaul is necessary to prevent contamination of the food by undesirable and hazardous products of combustion, such as nitrogen oxides, carbon monoxides, and sulphur compounds. Burners and ignition points require regular servicing to maintain combustion efficiency and overall process safety.

Indirect gas fired oven:

- The insulation of IFOs basically requires similar design and materials to those for DFOs.2

- Oven heat exchangers must be maintained regularly, as dirt and condensation (in steam-heated IFOs) may collect in their interior.

- All piping components (gaskets, fittings, and seals) must be dismantled for cleaning purposes.

- Replacement of faulty piping components and insulation material is essential to prevent heat leakage.4

References

- Manley, D. “Biscuit Baking.” Manley’s Technology of Biscuits, Crackers and Cookies, 4th ed., Woodhead Publishing Limited, 2011, p. 490.

- Fellows, P.J. “Baking and Roasting.” Food Processing Technology: Principles and Practice, 4th ed., Elsevier Ltd., 2017, pp. 735–740.

- Davidson, I. “Oven Designs.” Biscuit Baking Technology: Processing and Engineering Manual, 2nd ed., Elsevier Inc. , 2016, pp. 80–82.

- Singh, R.P. “Heat Transfer in Food Processing.” Introduction to Food Engineering, 5th ed., Elsevier Inc., 2014, p. 268.