Sheeter

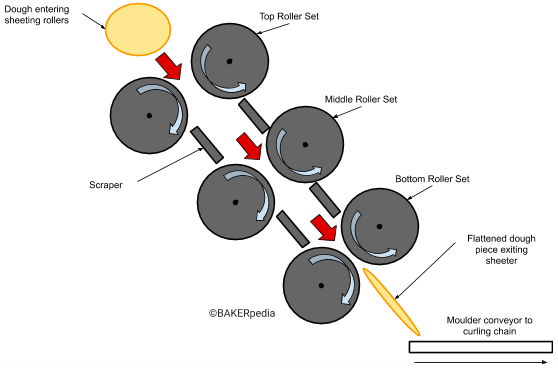

- Coming from intermediate proofing, rounded dough pieces are sheeted or gradually flattened through a series of rollers in preparation for final moulding. The sheeter is usually comprised of 2–3 sets (in series) of Teflon-coated roller heads between which the dough piece is passed to gradually flatten the dough piece.

- Sheeting applies stress forces (pressure) that help degas the dough piece so that large air cells developed during product transfer or intermediate proofing are reduced into smaller ones to achieve a fine grain in the finished product.

- Roller sets are arranged in such a way that the gap/clearance is reduced gradually as the dough travels through them. This is critical to promote a controlled reduction of dough thickness. It would be impossible to flatten dough pieces in one single step without causing irreparable damage to the gluten and gas cell structure.

- After passing through the top rollers, the dough piece becomes much thinner, larger, and oblong in shape. The flattened dough exiting the bottom rollers is ready to pass under the curling chain.

Final moulder

- The thin, flat dough pieces taken from the sheeter are moulded or formed into tight, uniform cylinders of the proper shape and length.

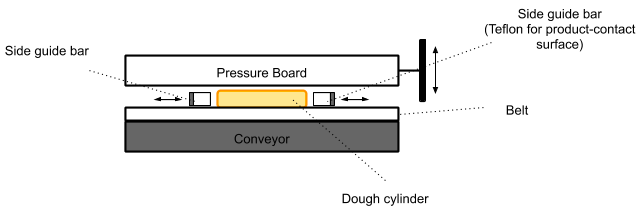

- The final moulder is, essentially, a forming conveyor which is equipped with 3 parts that define the product’s final dimensions.

Curling chain

As the dough piece exits the bottom head roller, it comes in contact with the curling chain. This causes the leading edge to slow down and begin curling back on itself. The weight of the curling chain begins the curling of the dough. Its length can be adjusted as needed.

When the dough piece exits the curling chain, it is completely rolled-up.

Pressure board and side guide bars

These parts give the dough piece its final loaf-type or cylinder shape by exerting downward/outward pressure and forcing the dough against side bars. This further de-gasses the dough pieces to form tight, uniform and sealed cylinders.

Application

Modern high-speed moulders have several variable speed drives for their different rollers and belts so that they can be fine-tuned for faster or slower production rates. There are two types of moulding equipment:1

- Straight grain moulder

- Cross grain moulder

Roller adjustments

| Sheeting roll set is too open (gap too wide) | Sheeting roll set is too tight (gap too narrow) |

|

|

Final moulder adjustments

Side guide rails and height of the pressure board of high-speed moulders can be adjusted to allow for a variety of dough piece sizes and lengths.

| Side guide bars | Pressure board |

|

|

Roller, side guide bars and pressure board settings can be adjusted to accommodate different dough rheologies or handling properties and should be set prior to the start of each variety. For example, processing whole wheat bread may call for less tight equipment settings, this is due to the lack of elasticity of whole wheat doughs.

References

- Therdthai, N., and Zhou, W. “Manufacture.” Bakery Products Science and Technology, 2nd edition, John Wiley & Sons, Ltd, 2014, pp. 476–485.