How it works

Traditional dough processing technology is focused on obtaining a very fine gas bubble structure in the dough and bread with a tight crumb grain. It’s designed for meeting the high volume and time efficiency demands of commercial bakeries. Such processing technologies rely on robust, durable equipment and technologies to secure the highest output in terms of pieces per minute.

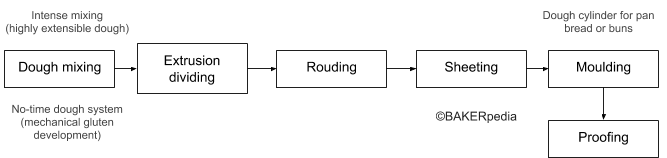

Today’s dough processing technologies are mainly used in pan bread and bun production. Such technologies can be designed, constructed and installed to operate with different dough systems. For example, sponge and dough, no-time dough, and liquid sponges. The dough system used is usually requested by the bakery at initial stages of production line sizing and planning.

Modern processing technology

Modern (alternative) dough processing technologies is focused on obtaining a less fine foam structure in the dough and a more open crumb grain in the finished product. It’s designed for production systems that are much more compatible with the concept of clean label, organic, and artisan-type breads. Such technologies usually operate at much lower speeds since the production line is designed for high flexibility, and in some cases, it is based on long fermentation steps and more delicate / slower dough forming during makeup.1

Application

Dough processing intended for breadmaking has traditionally been focused on short-time dough systems and the processing of highly refined wheat flours (i.e. flours which do not contain wheat bran and wheat germ). This approach has resulted in successful high-speed baking operations throughout the last decades. Traditional dough processing and its particular technologies are now being re-evaluated.

In recent years, consumer attention has been tending towards clean label products, which has led to less use of synthetic flour improvers by bakers, and substitution of chemical preservatives and other highly functional additives.

The greatest effort to improve the breadmaking performance of unrefined wheat flours (e.g. whole wheat, multigrain, etc.) has been focused on modifying the bread formula. Mainly, the addition of vital wheat gluten, oxidizing agents, dough strengthening enzymes, emulsifiers and hydrocolloids. Conversely, little attention has been given to adapting the breadmaking process to the different characteristics of the raw materials. The goal has always been developing a robust formulation to be process-tolerant and compatible with what is already present in the production line.2

Dough processing and product quality

The way dough is processed and handled has a direct impact on the finished product quality and characteristics.3 Despite the large diversity of bread characteristics across the globe, it can be said that bread quality is evaluated based on:

- Bread specific volume

- Crumb characteristics

- Crust color

These features are correlated with the raw materials and processing conditions used during breadmaking.

Characteristics of product directly impacted by dough processing methods

- Number and mean size of gas bubbles occluded in the dough during mixing

- Dough volume and hence dough density

- Integrity of the gluten-starch matrix (e.g. excessively high shear rates during makeup usually break up or degrade the gluten network)

- Gas holding ability of dough during proofing and baking (e.g. too large deformation forces used during makeup may even disrupt previously formed protein-protein bonds)

References

- Frank Devos, Traditional Versus Modern Leavening Systems, Cereal Foods World, 63, © 2018 AACC International, Inc.

- Ottavia Parenti, Lorenzo Guerrini, Bruno Zanoni, Techniques and technologies for the breadmaking process with unrefined wheat flours, Trends in Food Science & Technology 99 (2020) 152–166.

- Stear, C.A. Handbook of Breadmaking Technology, Elsevier Science Publishers Ltd, 1990.