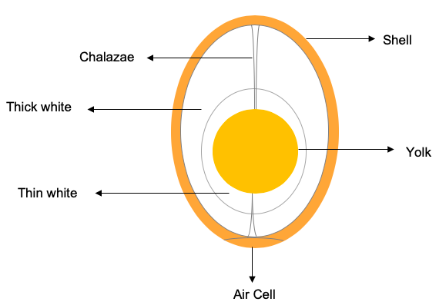

The following diagram details the different egg parts:

Origin

Chicken breeding originated in China approximately 3000 years ago. Artificially incubated eggs are believed to have been bred in ancient China and Egypt. However, it wasn’t until the 1870s that this practice was commercialized.1 Ancient Egyptians and Romans recognized eggs’ ability to thicken and texturize. They were the first to use domesticated chicken eggs in baking.

Function2

In baked products, they perform many functions including:2

- Binding: This property is related to their excellent texturizing properties, as well as lecithin’s contribution to its emulsifying capacity. Both characteristics are related to their proteins’ unique molecular structure and flexibility.

- Aeration: They produce foams when whipped, essential for volume build up, lightness and smooth mouthfeel. This is specially important for sponge cakes, genoise and angel cakes.

- Color and flavor: In baked goods, they provide a desirable yellow color, a characteristic of the yolk carotenoids. Egg proteins also participate in Maillard reactions responsible for desirable flavor and crust browning.

Other attributes include their effect on reduced staling, moistness and surface shine (egg wash), important for desirable organoleptic properties of baked goods.

Composition:2

| Component | Whole | White | Yolk |

| Moisture | 76% | 88% | 50% |

| Protein | 12% | 10% | 17% |

| Fat and emulsifiers | 10% | 0% | 30% |

| Other (sugars and ash) | 2% | 2% | 3% |

Nutrition

Eggs contain some of the highest quality proteins. They also contain vitamins, minerals, Omega-3, carotenoids and other antioxidants. However, they’re high in fats and cholesterol, which may increase the risk of heart diseases.2

Commercial production2,3

Egg products such as liquid, frozen or powder are obtained through the following production processes:

- Washing

- Shell breaking using subtle hit with hammers or knives

- Filtration to remove shell residues followed by pasteurization and refrigeration to produce refrigerated whole eggs.

- Whites and yolk separation by draining the yolk followed by pasteurization at 140 °F (60 °C) for 3.5 minutes in pressurized tanks or using heat exchangers.3 Liquid egg products should be stored at 40 °F (4 °C).

- Desugarization and spray drying to produce dried egg powder at 5% moisture and free of Maillard browning. Egg powders should be stored at room temperature in a cool dry area.

Application

Cakes, meringues, cookies, pastry creams and custards use eggs as main components to thicken, emulsify, build volume, stabilize and provide unique colors and flavors.

Egg whites are essential for the characteristic whipping ability and volume buildup in cakes where it acts as a leavening agent. While fatty acids in yolks contribute to the unique flavor and color development, lecithin is essential for its emulsifying power.

FDA regulations

The FDA classifies eggs (shell eggs) as potentially hazardous due to Salmonella Enteritidis. Similarly dry reconstituted and thawed frozen egg products are also considered potentially hazardous.2,4

References

- Food and Agricultural Organization. Poultry Meat And Eggs. Agribusiness Handbook. FAO, Rome, Italy, 2010, p. 7, http://www.fao.org/3/al175e/al175e.pdf . Accessed 1 Mar 2020.

- Figoni, P. How Baking Works: Exploring The Fundamentals Of Baking Science. 2nd ed., John Wiley & Sons, Inc., 2008, pp. 237-257.

- Nys, Y et al. Improving The Safety And Quality Of Eggs And Egg Products. Volume 1: Egg Chemistry, Production And Consumption. 1st ed., Woodhead Publishing Limited, 2011, pp. 4-5.

- Food and Drug Administration. “Egg Safety Final Rule”. Eggs Guidance Documents & Regulatory Information, 26 Jan 2019. https://www.fda.gov/food/eggs-guidance-documents-regulatory-information/egg-safety-final-rule. Accessed 1 Mar 2020.