Origin

Flour brews resemble sponge and dough systems, in which two mixing stages are used to produce a dough with the desired flavor profile, leavening, and dough development. Similar to water brews, liquid sponges became popular due to the need of high-speed and wholesale bakeries to become more flexible and consistently produce uniform doughs for the makeup stage. The adoption of liquid preferments by bakers was a result of the development of continuous mixing systems which allowed processing of both flour and water brews.

How does a flour brew work?

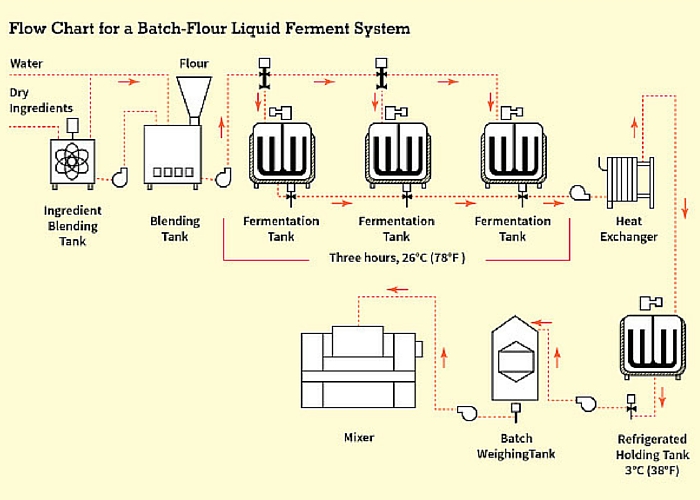

In flour brews, the fermentation step occurs in a liquid medium which is then pumped to be chilled, stored, and then mixed with the rest of flour and other ingredients to form the desired plastic dough.

Flour brew formula

Ingredients:1

- Flour (40% of total bread flour)

- Water (50% based on 100% flour) -A good rule of thumb here is to add 10–20% more water than flour

- Yeast (3.0%, in the form of cream)

- Sugar (1.0%)- Since flour is added to the brew, less sugar will be needed as yeast nutrient.

- Buffering agents (0.1–0.25%) – At flour levels lower than 40%, calcium carbonate or other calcium salts may be needed to control pH drop.

Process:1

- Scaling/metering of brew ingredients.

- Blending/agitation to incorporate ingredients at high speed (2–6 minutes at 26°C ( 79°F)).

- Transfering or pumping to the fermentation vessel.

- Fermentation with gentle agitation at 26°C (79°F) for 60–180 minutes. The brew usually starts out with a pH of 5.0–5.5 and total titratable acidity (TTA) of 3.0–4.0, and finishes with a pH higher than 4.6 and TTA higher than 8.0. Final temperature for the fermented brew is typically 29–32°C (85–90°F).

- Chilling through heat exchanger to a temperature of 3–5°C (37–41°F), to stop or slow down fermentation .

- Holding for 8 hours at 3–5°C (37–41°F) until it is ready for use in dough mixing.

Application

Using flour brews provides bakers with production flexibility since the same ferment or an intermediate product can be used for multiple batches or types of dough.

Advantages and disadvantages of flour brew compared to other preferment systems:2,3

| Advantages |

|

| Disadvantages |

|

pH and TTA should be properly measured and controlled during fermentation to obtain the desired characteristics in the flour brew. For example, high TTA is generally beneficial for better flavor development. However, very high TTA may result in sour tasting dough.

Dough mixing time at the developer (for continuous mix systems) or horizontal mixer is a function of flour in the brew. As in the sponge and dough system where more flour is fermented and matured, less mechanical development of the dough is needed. Therefore, as flour increases in the brew, dough mixing time is reduced. As flour decreases, mixing time increases.

Equipment involved in processing and handling flour brews should allow for maintenance, inspection and cleaning activities to be performed properly to reduce downtime.

Stainless steel blending, fermentation and holding tanks, piping, heat exchangers (tubular or plate), pumps, can be all cleaned-in-place (CIP) by using high-pressure spraying/jetting and turbulent flow procedures. The frequency of cleaning tasks depends on the nature of the process and sanitation standards established in the bakery.

References

- Carson, L. “Flour Preferment” Dough Systems. A Guide On Formulating Sponge and Dough, Preferments and Straight Dough Systems, BAKERpedia, LLC, 2017, pp. 12–15.

- Moore, T.R. “Breads” Encyclopedia of Food Grains, vol. 1, Elsevier Ltd., 2016, pp. 8–12.

- Tomoskozi, S., and Bekes, F. “Bread: Dough Mixing and Testing Operations” Encyclopedia of Food and Health, vol. 3, Elsevier Ltd., 2016, pp. 490–493.