Origin

The sponge and dough system became popular in the 70s and 80s after the somewhat “poor” experience of American high-speed bakers with the continuous mixing system. So, bakers became aware of the time needed for the dough to properly ferment, naturally mature the flour and improve the overall quality of bread.

How sponge and dough works

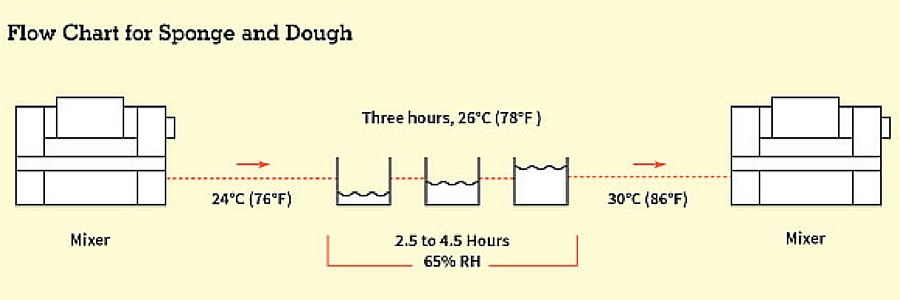

The sponge and dough method consists of two distinct mixing stages.

Stage 1: Making the sponge

In this stage, 60%–90% of the total flour is combined with water at room temperature to a 58–65% hydration level (based on sponge flour weight). Then, compressed yeast at 1.5–5.0% (based on total flour weight) is added and shortly mixed just to incorporate ingredients. Next, fermentation follows for 2–8 hours at 75–85°F (24–29°C) and relative humidity of 60–80% to produce the sponge.1,2

Sponge fermentation time varies with:1,2

- Temperature

- Ingredients used

- Amount of yeast

- Available food like sugars and damaged starch in flour

- Amylase activity of flour

- Water absorption of sponge

- pH of sponge

In small-scale sponge production, the sponge is mixed and stored in the mixer. However, in high-speed bakeries, a separate container such as a trough is used to store the sponge in a fermentation room under controlled conditions. Occasionally, the sponge must be knocked, or punched down, to prevent it from spilling over.

Stage 2: Making the dough

The sponge is added to the remaining liquid and dry ingredients and mixed for 8–16 minutes in a horizontal mixer to form a dough of optimum gluten development. Then, the dough goes to the makeup stage, where it is proofed and baked.1,2

Once pre-fermentation is complete, the sponge:

- Expands 4–5 times its volume

- Is very soft, pliable, extensible, with an open cell structure

- Has risen 8–10°F (4.5–5.5°C) in temperature.

- Has a temperature of 84–88°F (29–31°C)

- Has a pH of 4.8–4.9

- Has a total titratable acidity (TTA) of 4.5–4.6

Commercial production

The sponge and dough system is still popular in small bakeries but has been gradually replaced in commercial bakeries by faster production systems such as the straight or no-time dough.

When using a sponge and dough system, commercial bread manufacturers use a combination of mixing methods that include horizontal and Tweedy mixers. Automation and ingredient handling systems have created faster production times and a semi-continuous mixing fashion with sponges being produced without schedule interruption to feed the sponge and dough system.

The sponge and dough system is currently experiencing a vigorous come back with trends such as clean label.

Application

Since the sponge and dough is already ripe prior to mixing into the final dough, in addition to accelerating fermentation, it is itself a partially developed dough. So, these aspects help in reducing mixing time.

The best flour to use in the sponge is:

- Milled from hard wheat

- 13–15% protein content

- Sufficient level of damaged starch to provide food for yeast

- Optimum amylase activity (Falling Number of 200–250 seconds)

Along with temperature and time, TTA and pH measurements are the best and most practical ways to control and monitor the sponge fermentation step. Acidification of the sponge is an indication of good fermentation and enzymatic activity.

Advantages and disadvantages of the sponge and dough system

| Advantages | Disadvantages |

|

|

References

- Moore, T.R. “Breads.” Encyclopedia of Food Grains, 2nd edition, Volume 3 Grain-Based Products and their Processing, Academic Press, Elsevier Ltd., 2016, pp. 8–18.

- Cauvain, S.P. “Breadmaking Processes.” Technology of Breadmaking, 3rd edition, Springer International Publishing Switzerland, 2015 pp. 23–54.