Origin

Tapioca flour is obtained from the roots of the cassava plant (Manihot esculentus), which is found in equatorial regions between the Tropic of Cancer and the Tropic of Capricorn. Names for the cassava plant vary, depending on the region:

- Yucca (Central America)

- Mandioca (Brazil)

- Tapioca (India and Malaysia)

- Cassava (Africa and Southeast Asia)

Function

Tapioca flour is a very versatile ingredient. It can perform the following functions:

- Formation of gels (upon cooking)

- Thickening of batter and dough for higher gas bubble stability

- Adhesion or binding effect for gluten-free formulations

- Moisture-retention of bread and buns

- Serve as a texturizing and stabilizing agent in icing formulations

Nutrition and health

Tuber and root flours/starches contain less fat and protein compared with their cereal counterparts. As a consequence, tapioca flour is very bland in flavor. The average composition of tapioca flour:1

| Component | Tapioca flour (%, wet basis) |

| Moisture | Max. 12.0 |

| Starch | Min. 60.0 |

| Cyanide content | Max. 10 mg/Kg |

| Ash | Max. 0.35 |

| Total acidity | Max. 0.2 |

| Crude fiber | Max. 0.2 |

Cyanogens in tapioca

When cassava roots are to be used in the human diet or as animal feed, the toxicity of cassava is important. Cyanogenic glucosides are present in all parts of the cassava plant, including the edible roots.2

Proper processes such as wet milling, cooking, boiling, drying, enzyme modification, frying and fermentation are employed to effectively detoxify cassava and produce products with a safe level of hydrogen cyanide.2

Commercial production

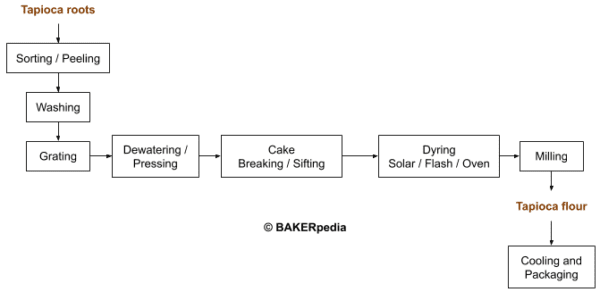

Tapioca flour is produced on a commercial scale from milled dried cassava chips or wet mash. Mashing of cassava root is achieved by grating or milling of peeled roots. The mash obtained in the initial stages can either be fermented or unfermented.

The following block diagram shows the production process for tapioca flour:

Application

Cassava flour can be used in the production of gluten-free mixes, batter cakes, rolls, pan, artisan and sourdough bread. It can be added to yeast-leavened products at levels up to 15% without greatly affecting gas retention properties of the composite dough.

As rules of thumb, the higher the level of inclusion:

- The lower the resistance to deformation of extension (P value on alveograph, torque in farinograph).

- The more different the dough behaves. Dough absorption may change drastically with high inclusion levels. Tapioca flour has a very fine particle size and has a far superior surface area than patent or whole wheat flour.

- The more different the gelatinization, pasting, and retrogradation behavior of the product versus standard wheat flour dough.

- The lower the gelatinization temperature range for the dough or batter system during baking.

- The lower the volume of pan bread. Under this scenario, high specific volume white bread might not be the best application. Adding more tapioca starch causes product to become more dense

- The less sticky the dough becomes as a consequence of high competition for water absorption.

Relevant parameters for tapioca flour and its comparison with other starchy sources2,3

| Starch type | Amylose content (%) | Amylopectin content (%) | Gelatinization temperature (°F / °C) |

| Tapioca | 17 | 83 | 149–158 / 65–70 |

| Potato | 20 | 80 | 140–149 / 60–65 |

| Wheat | 25 | 75 | 176–185 / 80–85 |

| Waxy corn | <1 | >99 | 149–158 / 65–70 |

| High-amylose corn | 55–70 | 45–30 | 140–169 / 60–76 |

FDA regulation

Given its source, tapioca flour is an unrestricted food ingredient for use in a wide range of food industries.

References

- Obadina, A.O., and Adekoya, I.O. “Controlling Food Safety Hazards in Root and Tuber Processing: An HACCP Approach.” Tropical Roots and Tubers Production, Processing and Technology, John Wiley & Sons, Ltd, 2016, pp. 301–324.

- Breuninger, W.F., Piyachomkwan, K., and Sriroth, K. “Tapioca/Cassava Starch: Production and Use.” Starch: Chemistry and Technology, 3rd edition, Academic Press, Elsevier, Inc., 2009, pp. 541–568.

- Thomas, D.J., and Atwell, W.A. “Starch Structure.” Starches, Eagan Press Handbook Series, American Association of Cereal Chemists, Inc., 1999, pp. 1–11.