Origin

Water blending systems are currently gaining a lot of attention in the snack and bakery industry. High speed bakery operations handling large amounts of raw materials and using bulk ingredient handling systems require accuracy and consistency in liquid ingredients metering and strict control over dosing temperature.

How does it work?

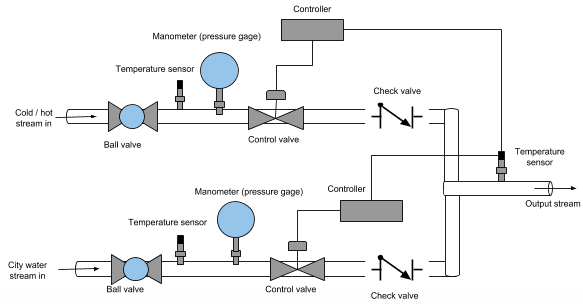

A water blending system can come with a configuration that allows bakers to combine 2 or 3 water streams to produce a single water output at a preset temperature and/or flow rate.

In this system, one of the 2 or 3 streams (pipe sections) is regular water that may come from the city’s water supply (this water stream is not heated or chilled). The other streams, depending on the blending system, can be hot and/or chilled water.

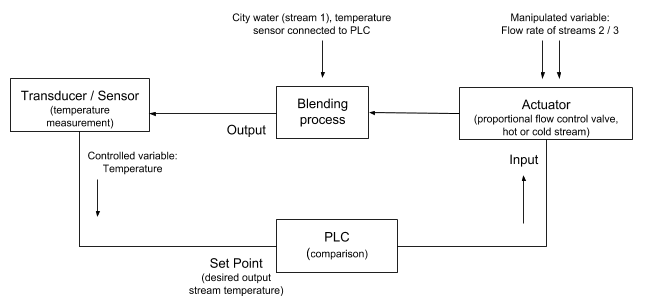

For simplicity and cost-effectiveness, water blending systems often use a feedback controlled closed loop. The water blender’s instrumentation and control system monitors the temperatures of the incoming city water and the outgoing water blend (output). The following block diagram helps understand a control system used in such cases.1

Block diagram of feedback controlled closed loop system.

Depending on the desired temperature of output stream (set by the bakery based on process needs), the water blending system determines whether it will blend the city water with the hot or cold stream. The control system uses the blended water (output stream) temperature to determine where to (and to what extent) adjust the individual stream’s control valves.

A control panel with touch screen (HMI) for temperature and volume selection is usually used to control the blending valves.

Simplified representation of a 2-stream water blender.

Application

A water blending system has some differences than other indirect heat exchangers in some ways. A water blending system can be seen as a direct heat exchanger. Unlike indirect heat exchangers such as plate and tubular that do not come into contact with the product, the water blender directly adds a hot or cold stream to tap water to obtain a desired temperature and flow rate instantaneously.2

Stainless steel used for piping, instrumentation and accessories. Stainless steel (SS) is a family of chromium (Cr) containing alloys with a minimum Cr content of 11–12%. The water blending system uses SS 300 series, more specifically AISI SS 304 for piping and AISI SS 316 for valves.

Some characteristics of these types of SS include:3

- Excellent corrosion resistance (improved by incorporating molybdenum, Mo).

- Excellent weldability, particularly the L (low carbon) grades.

- Good strength and hardness.

- Surface with a mean roughness (Ra) of 0.5 μm. Smooth surface finish helps improve line cleanability (proper pump and line installation is needed to guarantee cleanability throughout the blender line.

- Type 304 has a composition of 18–20% Cr, 8–12% nickel, 0.08% maximum carbon, 2% maximum manganese, and 1% maximum silicon.

- Grade 316 has a similar composition except that the Cr is reduced to 16–18%, and 2–3% Mo is added.

- The main limitation of 300 SS series in the food industry is that these grades are susceptible to halides, particularly chloride ion attack resulting in pitting. It is recommended to keep low chloride levels (up to 50 mg/L or ppm) during cleaning and sanitizing cycles.

References

- Bhuyan, M. “Measuring and Controlling Devices.” Measurement and Control in Food Processing, CRC Press, Taylor & Francis Group, LLC, 2007, pp. 27–103.

- Singh, R.P. “Heat Transfer in Food Processing.” Introduction to Food Engineering, 4th edition, Academic Press, Elsevier Inc., 2009, pp. 247–260.

- Murray, A.N. “Hygienic Design of Equipment.” Encyclopedia of Food Safety, Volume 4, Academic Press, Elsevier Inc., 2014, pp. 181–188.