How it is measured ?

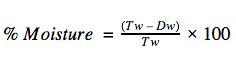

The mathematical expression of the moisture content of a product is:

Where Tw = total weight of product, and Dw = dried weight of product.

It can be measured using direct and indirect methods. While direct methods remove the water from the sample test, indirect methods predict it by either under accelerated heating or by correlating moisture to another measured parameter. The following are some of the most reliable tests used in food applications:

Direct methods:

- Evaporation—Vacuum, Air and Microwave ovens, infrared (IR)

- Chemical reactions—Karl-Fischer method

- Distillation—Dean and Stark method

Indirect methods:

- Spectroscopy—Nuclear Magnetic Resonance (NMR)

- Thermogravimetric—Thermal Gravimetric Analysis (TGA)

- Calorimetric—Differential Scanning Calorimetry (DSC)

- Differential Thermal Analysis (DTA)

- Dielectric Moisture Meter

In cereal processing, the most commonly used method is the AACCI Approved Method 44-15.02. It measures moisture directly as sample weight loss upon heating under specific drying conditions, although more accurate methods have been developed for assessing the content in cereal products.2

Typical moisture content of food products

| Food item | Percent moisture (wet weight basis)* |

| Whole wheat grain | 12.0 |

| Tempered wheat grain | 15.0–18.0 |

| Wheat flour from whole grain | 10.0–10.5 |

| Wheat (enriched, white) flour | 13.0–13.5 |

| Crackers (saltines) | 4.0 |

| Biscuits | 3.0 |

| Dried pasta / macaroni | 10.0–11.0 |

| Cow’s milk (whole) | 87.0 |

| Bread dough | 40.0 |

| Freshly baked bread | 35.0 |

| Raisins | 15.3 |

| Margarine (regular, hard, hydrogenated) | 15.5–16.0 |

| Cheddar cheese | 36.0–37.0 |

| Walnuts (black, dried) | 4.6 |

| Peanuts (roasted) | 1.5–2.0 |

| Peanut butter | 1.5–2.0 |

| Honey | 17.0–18.0 |

| Sugar (granulated) | 0.0 |

| Dried whole egg | 5.0 |

* Wet weight basis is the standard computation for moisture content.

Application

Moisture or water content is a very important parameter in the food industry due to its role in determining the product’s:

- Shelf-life and overall stability. Generally speaking, low-moisture foods (more accurately low water activity) have lower enzymatic activities and reduced microbial growth (fungal and bacterial).

- Economical value. Moisture content is critical in ingredient purchasing decisions. The lower it is, the higher is the solids content (protein, starch, fat, sugars, ash) and the higher its value.

- Packaging. Moisture content determination is essential for selecting appropriate packaging material. High moisture content food products require packaging materials with better moisture barrier properties.

Despite the importance of gross moisture content in characterizing food products and predicting their shelf life, determining whether the water is ‘bound’ or ‘free’ is of utmost importance.

Only free water has the ability to support microbial growth and biochemical reactions. The term water activity or Aw was developed to help describe the amount of state of the water in a given system.

The higher the Aw, the more likely the food will support microbial growth and will have a shorter shelf life, and vice-versa. Microorganisms such as molds, yeast and bacteria require water contents that allow molecular mobility and enhance their growth in a food material. This only occurs at Aw > 70%.3

References

- Mauer, L.J., and Bradley Jr, R.L. “Moisture and Total Solids Analysis” Food Analysis, 5th edition, Springer International Publishing, 2017, pp. 257–286.

- AACC International. Approved Methods of Analysis, 11th Ed. Method 44-15.02. Moisture—Air-Oven Methods. Approved November 3, 1999. AACC International, St. Paul, MN, U.S.A.

- Damodaran, S. “Water and Ice Relations in Foods.” Fennema’s Food Chemistry, 5th edition, CRC Press, Taylor & Francis Group, LLC, 2017, pp. 19–90.