Origin

The concept of no time or short time dough process became popular in the 1950s and 1960s when global demand for bread started to increase dramatically. This urged wholesale bakers to become more time efficient and produce more batches of bread per day.

How does it work?

The goal of the straight dough process is to obtain a high-quality and standardized bread batch in a very short time (3–4 hours from scaling through packaging compared to 6–8 hours in the sponge and dough system). This helps bakers comply with unexpected customer orders and offer a better service through reduction of lead and cycle times.

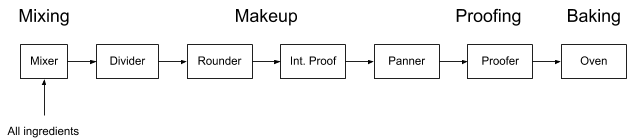

The following diagram shows the steps for the production of pan bread using the straight dough system:

In this system, the yeast and dough conditioners quickly modify the rheology of the dough to obtain optimum dough handling properties for makeup and gas retention for target volume during proofing and baking.

Application

The goal of the straight dough system is to match the finished product quality of bread made with a normal and/or long fermentation time. This is accomplished through proper processing and the right formulation.

Formulation considerations for straight dough system

- Dough conditioners. Addition of a dough conditioner concentrate (1.0–4.0% based on flour weight). The mix should contain a fast-acting reducing agent (e.g. L-cysteine), a slow-acting oxidizing agent (e.g. potassium bromate, ascorbic acid), emulsifiers (to provide softness to dough and extend bread shelf-life), and enzymes (proteases to increase dough extensibility and amylases for slowing down staling).

- Water. Addition of extra water (2–3% more compared to sponge and dough, based on flour weight) to boost yeast and enzyme activity by lowering osmotic pressure, increase dough extensibility for machining.

- Salt. Adjustment of salt and sugar levels may be necessary. To enhance flavor, add 0.1–0.3% more salt (based on flour weight). Salt slows down yeast activity, so with the higher salt level, more yeast may also be needed to maintain same proofing times.

- Yeast. Addition of extra yeast (1.0–1.5% more compared to sponge and dough, based on flour weight) to optimize gassing and keep proofing times within schedule.

- Yeast food. In no time doughs, no additional sugars are needed because there is no fermentation. Higher levels of residual sugars may result in a finished product with a darker crust color. To reduce this effect, use 1–2% less sugar based on flour weight.

- Damaged starch in flour is not relevant in the no time dough process. Since there is not enough time for enzymes to gradually convert damaged starch into simple sugars, sucrose or liquid sweeteners will provide nutrients for yeast to use during proofing and oven spring.

- Acids. Add acidulants (e.g. MCP, vinegar) to quickly reach optimum pH (5.5) for yeast activity and performance of mold inhibitors.

- Mold inhibitors. Calcium propionate (Cal-Pro) or other mold inhibitors should be increased given the higher water absorption level. A 65% water absorption dough uses 0.25% of Cal-Pro, whereas a 67% hydration dough may require 0.40% for equivalent mold-free shelf-life.

Processing considerations

- Mixing. Dough mixing should be long enough to reach proper gluten development (typically 12–18 min at high speed in a horizontal mixer).

- To shorten mixing times, it is advisable to delay fat, sugar and salt addition. This helps gluten hydrate and develop quickly (clean-up takes much less time), and provides maximum friction against mixer bowl.

- Dough temperature. Dough temperature at the end of mixing should be at 82–86°F (28–30°C). This helps to boost yeast activity and slightly decrease elasticity and resistance to deformation for good machining.

Advantages and disadvantages of using the straight dough process

| Advantages | Disadvantages |

|

|

References

- Sievert, D., Hoseney, R.C., and Delcour, J.A. “Bread and Other Baked Products.” Ullmann’s Food and Feed, Volume 2, Wiley-VCH Verlag GmbH & Co., 2017, pp. 462–507.