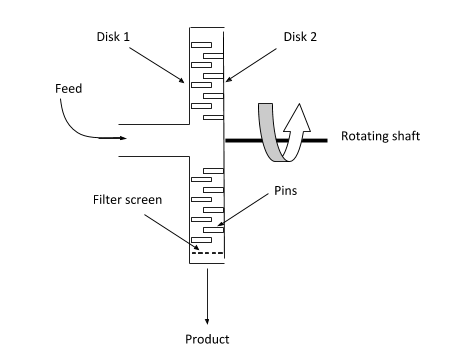

Disk sets in pin mills can have two different operating configurations:4

- One of the disks is maintained static (called stator) while the other is rotated (called rotor).

- Both disks may rotate either in the same or in opposite directions at different speeds.

The incoming material is gravity fed through the centrally located inlet of the stator disc. Centrifugal forces accelerate the materials in such a way that they reach the striking zone where they are subjected to strong impact and shear forces between the pins.

Pin mills may have a filter screen of a given mesh or aperture opening fitted over the whole or part of the equipment periphery. After grinding, the reduced particles are forced to pass through the screen from where they are collected and discharged. Pin mills may be fitted with jackets for temperature control. Such mills are suitable for heavy duty operations, and grinding to maximum fineness.4

Size reduction efficiency with a pin mill is a function of the following variables:

- Rotation speed of the motor

- Mass flow of incoming material (load)

- Rotation pattern of disks (e.g., differential speed, counter-rotating design)

- Design and arrangement of pin breakers

- Hardness or resistance to breakage of materials being milled

- Gap between disks

- Target particle size of milled product (initial particle size/final particle size ratio)

- Energy consumption in KWh/ton, or electric current consumed by motor

The following is a schematic representation of a pin mill:

Application

Particle size of pin-milled grains vary greatly with the configuration of the discs and their rotation orientation. Single-disc rotation results in powders with 5-100 µm particle size while dual-disc rotation can produce finer powders (as low as 2μm).5 This is a clear illustration that pin mills may be used for either coarse grinding, fine grinding, or for deagglomeration purposes.

Flexibility and range of applications of pin mills are a function of operation mode and configuration of the equipment used. Pin mills can be used for:4

- Cracking wheat

- Grinding legumes

- Obtaining barley grist as adjunct for malting and brewing plants

- Producing cake flour from various flour streams of hard wheats

- Creating powdered sugar

- Conditioning cellulose fiber

Relevant considerations

- Pin milling as a grinding mechanism must be followed by sieving and purifying (removal of bran layers, and classification of middlings and other endosperm particles according to particle size and density).

- Pin mills are effective in reducing the particle size of cereal materials in short times. However, at high speeds and longer processing times, they can produce high levels of fractured or damaged starch. Depending on the baking application, this could be undesirable.6

References

- Serna-Saldivar, S.O. “Glossary.” Cereal Grains: Properties, Processing, and Nutritional Attributes, Taylor & Francis Group, LLC, 2010, p. 694.

- Posner, E.S. “Wheat Flour Milling.” Wheat Chemistry and Technology, 4th ed., AACC International, Inc., 2009, pp. 132–133.

- Boulton, C. “P.” Encyclopedia of Brewing, John Wiley & Sons, Ltd., Publication, 2013, p. 463.

- Da Costa, S.B. “Dry Milling.” Engineering Aspects of Cereal and Cereal-Based Products, Taylor & Francis Group, LLC, 2014, pp. 104–105.

- Saravacos, G.D., and Maroulis, Z.B. “Mechanical Processing Operations.” Food Process Engineering Operations, CRC Press, imprint of Taylor & Francis Group, 2011, p. 175–177.

- Delcour, J.A., and Hoseney, R.C. “Dry Milling.” Principles of Cereal Science and Technology, 3rd ed., AACC International, Inc., 2010, p. 119.