Function

It is used in bread, buns and many other yeast-leavened bakery products at levels of 0.2–0.6% (based on flour weight). DATEM possesses excellent dough strengthening properties due to its ability to adsorb at the gas/liquid interface of dough and stabilize the foam structure trapped by the gluten matrix and prevent gas bubble coalescence.1,2 So, DATEM enhances gas (CO2) retention and improves tolerance to shocks in case of mechanical abuse during final proofing and baking.

Due to its anionic nature, DATEM also has the capacity to interact with gluten proteins, promoting protein aggregation.2

Commercial production

DATEM are composed of:

- Glycerol derivatives esterified with edible fatty acids, and

- Mono and diacetyl tartaric acids.

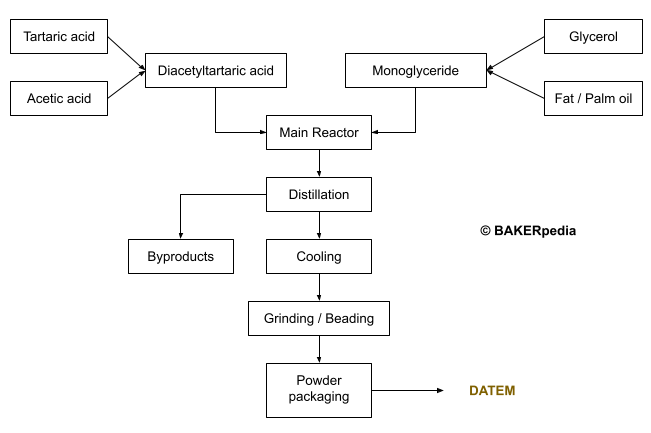

There are two different processes needed for the production of these species that make up DATEM:2

- The esterification of mono- and diglycerides with tartaric and acetic acids in the presence of acetic acid anhydride.

- The reaction of diacetyl tartaric acid in the presence of acetic acid with mono- and diglycerides. First, the diacetyl tartaric acid is produced from the reaction of diacetyl tartaric acid with acetic acid. The acetic acid generated in this reaction has to be removed by distillation. The final reaction with monoglycerides is possible once acetic acid is removed.

Application

For ease during scaling and handling, DATEM is usually sold as a powder. The powder form also allows for a cost-effective logistics between supplier and bakery and a lower carbon-footprint in the bakery supply chain. There are also DATEM replacements available.

Properties of commercial DATEM include:

- Melting point: about 45°C. True melting point depends on the chain length and saturation of the fatty acids present in the molecule)

- Powder with 2% moisture (max)

- Purity indicador (total tartaric acid content): min. 10, max. 40%

- Solubility in water at 20°C: dispersible

- Solubility in vegetable oils at 20°C: partially soluble

- HLB value: 9–10 (excellent oil-in-water emulsifier)

- Amylose complexing index (crumb softening ability): 49 (fair)

- Synergistic ingredients: SSL, CSL

In practice, DATEM may help:

- Reduce levels of vital wheat gluten

- Increase water absorption slightly

- Decrease amount of yeast needed for optimum dough expansion during oven spring

- Increase dough tolerance to over-proofing caused by unexpected line stoppages

Regulation

DATEM is a controlled food additive under the E-number 472. It holds a GRAS status by the FDA.3

In the EU, DATEM (E472e) is authorized as a food additive (EC-Regulation, No. 1333/2008).

References

- McClements, D.J. “Emulsion Ingredients.” Food Emulsions: Principles, Practices and Techniques, 3rd edition, CRC Press, Taylor & Francis Group, LLC, 2016, pp. 99–176.

- Gaupp, R., and Adams, W. “Diacetyl Tartaric Esters of Monoglycerides (DATEM) and Associated Emulsifiers in Bread Making.” Emulsifiers in Food Technology, 2nd edition, John Wiley & Sons, Ltd, 2015, pp. 121–142.

- Federal Register: Electronic Code of Federal Regulations, Title 21, Chapter I, Subchapter B, Part 184 – Direct Food Substances Affirmed as Generally Recognized as Safe, https://ecfr.federalregister.gov/current/title-21/chapter-I/subchapter-B/part-184, Accessed 1 November 2020.

- Colakoglu, A and Özkaya, H. “Potential use of exogenous lipases for DATEM replacement to modify the rheological and thermal properties of wheat flour dough.” Journal of Cereal Science,Volume 55, Issue 3, 2012, ISSN 0733-5210. https://www.sciencedirect.com/science/article/abs/pii/S0733521012000422?fbclid=IwAR170KE53BredxMO0ENJJyJPS8TGD6k1nhcoRYvQDgnkO6jlxqfkoIkVIcE

- Abdullah S. Colakoglu, Hazım Özkaya. “Potential use of exogenous lipases for DATEM replacement to modify the rheological and thermal properties of wheat flour dough.” Journal of Cereal Science, Volume 55, Issue 3, 2012. ISSN 0733-5210. https://www.sciencedirect.com/science/article/pii/S0733521012000422