Origin

Almost all GOX preparations available on the market are produced by Aspergillus niger and other species belonging to that fungal genus. Production of glucose oxidase is believed to be a survival mechanism for fungus under certain adverse conditions.

Function

The following table summarizes some key aspects of GOX when used in high-speed breadmaking:

| Enzyme | EC Number | Substrate | Reaction catalyzed | Ingredient replaced |

|---|---|---|---|---|

| Glucose oxidase | 1.1.3.4 | β-D-glucose | β-D-glucose + O2 → Gluconic acid + H2O2 Hydrogen peroxide is the true oxidizing agent. GOX is only the means to and end. | ADAPotassium bromate

Ascorbic acid |

GOX irreversibly oxidizes β-D-glucose to glucono-δ-lactone, which is immediately converted to gluconic acid in the presence of water. In addition to glucose, it oxidizes a number of aldose molecules such as α-D-glucose, mannose, xylose, and galactose.2

GOX addition to yeast-leavened systems creates oxidative conditions which promote the formation of a superior or more developed polymeric network through one or a combination of the following mechanisms:3

- Oxidation of sulfhydryl (SH) groups and formation of higher amounts of disulphide (S–S) bonds that bring separate protein chains together.

- 2R–SH (2 cysteine residues from separate protein chains) + H2O2 from GOX → R–S–S–R’ (cysteine molecules link and bring protein chains together)

- Non-disulphide protein cross-linking (aggregation) by formation of dityrosine bridges between separate gluten-forming chains. This is possible due to the oxidation of tyrosine residues. This mechanism is highly appreciated in gluten-free formulations rich in egg proteins.

- Oxidate gelation of beneficial WE-AXs which further strengthens the gluten-starch matrix. Ferulic acid residues link adjacent AX chains by forming diferulic acid bridges.

When adding GOX to bread and bun formulations, the ultimate goal is to produce hydrogen peroxide H2O2 and create the necessary oxidizing conditions that provide the dough strengthening effects.

Commercial production

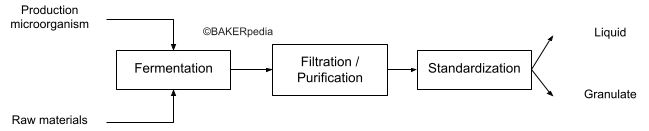

Large scale production of GOX relies on fermentation and downstream processing using modern biotechnology. The enzyme is typically obtained from fungal sources, such as Aspergillus oryzae or Penicillium chrysogenum.

The following diagram summarizes the commercial production of GOX:

Application

The addition of GOX creates a stronger dough which renders the following results:

- Higher loaf volume

- Reduced dough stickiness due to surface drying effect of hydrogen peroxide

- Superior oven spring and gas retention

- Improved (more even and tighter) crumb structure

- Increased tolerance to overproofing and gas bubble coalescence due to unexpected line stoppages

- Reduced use of vital wheat gluten

- Slightly increased water absorption

Like any other enzyme, functionality of GOX in the bakery industry is affected by temperature, pH, ionic strength, and moisture level in the dough impacted by flour hydration.

As GOX requires both oxygen and glucose, its strengthening effect on the bulk rheology of the dough occurs mainly during mixing, where oxygen is not limited. In later stages of the breadmaking process, such as proofing and baking, the reaction rate and GOX functionality is yet to be fully understood. It is reasonable to assume that GOX action stops quickly after mixing as the oxygen incorporated as air during mixing is rapidly consumed by yeast.

Regulation

GOX is GRAS (Generally Recognized as Safe) and considered a food processing aid according to the Codex Alimentarius. The FDA regulates their origin (food-compatible) and establishes limits to their use (if applicable) based on GMP.

References

- Sandip B. Bankar, Mahesh V. Bule, Rekha S. Singhal, Laxmi Ananthanarayan, Glucose oxidase — An overview, Biotechnology Advances, Volume 27, Issue 4, 2009, Pages 489-501.

- Vroemen, A.J. “Glucose Oxidase.” Handbook of Food Enzymology, Marcel Dekker, Inc., 2003, pp. 425–432.

- Hamer, R.J., MacRitchie, F., and Weegels, P.L. “Structure and Functional Properties of Gluten.” Wheat Chemistry and technology, 4th edition, AACC International, Inc., 2009, pp. 153–172.