Origin

This ingredient was first developed in Central and South America, though its origins are not completely known. When Hernán Cortés conquered the Aztecs, he brought it and cacao beans back to Spain, where it flourished. From there, this good spread throughout Europe. Today, this food ingredient and product is the number one preferred flavor of North Americans and Europeans.

Function

Dark, bittersweet and semi-sweet varieties are widely used in many types of pastries, confections, and desserts. It can also be eaten out of hand. It has two major distinguishing characteristics: its flavor and its texture. Over 1,500 flavor components have been identified in this one ingredient, making it one of the most complex food ingredients out there.

It is typically solid at room temperature (70–75°F/20–25°C) and melts rapidly in the mouth at 98.5°F (37°C). The rheology of this ingredient is affected by factors including particle size, the solid fat profile of cocoa butter, conching, the melting point of cocoa butter, and the presence of emulsifiers or stabilizers.1,2

Nutrition and health

Although chocolate and other cocoa‐containing products are often viewed as an indulgence food given their high fat and sugar content, these products contain a number of essential minerals and vitamins, as well as non‐nutritive bioactive components including polyphenols, methylxanthines, and mono-unsaturated fatty acids.3

Emerging evidence suggests that cocoa has beneficial health effects related to cardiovascular disease, metabolic syndrome, neurodegenerative diseases, and other chronic health conditions.3

Commercial production

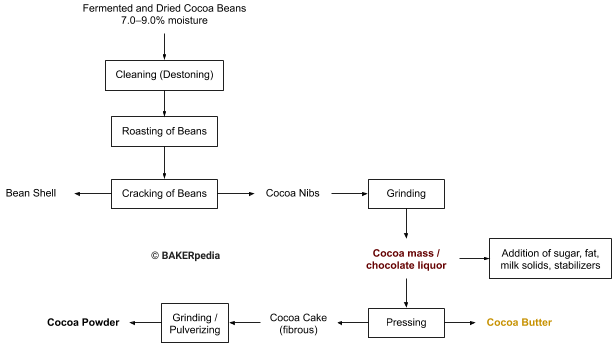

Cocoa beans are harvested, split open, dried and fermented, further dried and then crushed into cocoa nibs. Various classes of products can be obtained, such as:

- Cocoa butter: fat component of cocoa beans with a sharp melting point just below body temperature

- Cocoa mass (liquor): liquid or semi-plastic component that contains 50–58% by weight of cocoa fat

- Cocoa solids: nonfat (fibrous) part of the cacao bean

It is produced according to the following cocoa processing diagram:

Application

Types of this ingredient used include;

- Liquor (also known as baker’s chocolate): an unsweetened and plain form of chocolate. This is chocolate in its rawest form and has a bitter taste. It is used as an ingredient in sweet goods that adds color and chocolate flavor.4

- Sweet: a form of chocolate with added sugars. The amount of sugar or sweetness can vary depending on the application and customer requirements.4

- Milk: a form of chocolate that contains milk solids, sugar, and other ingredients. It is lighter in color than semi-sweet and baker’s chocolate.4

- White: a mix of cocoa butter, sugar, milk solids, and salt.4

In baking, chocolate provides structure and absorbs moisture. Cakes formulated with chocolate usually need more water and whole eggs than those without cocoa products. It adds texture as well, due to its fat content.

Chocolate liquor is the base material or starting point of all cocoa-based products used in bakery and confectionery applications.

Composition of chocolate liquor:4

| Component | % (Range) |

| Moisture | 0.5–3.5 |

| Protein | 9.0–13.0 |

| Starch | 5.0–7.0 |

| Fat (cocoa butter) | 50.0–58.0 |

| Total sugars | 1.0–3.0 |

| Total ash | 2.0–4.0 |

| Cellulose | 9.0–12.0 |

| Pentosans | 1.2–1.6 |

| Polyhydroxyphenols | 4.0–4.6 |

| Organic acids | 1.1–1.7 |

| Theobromine, caffeine | 1.2–1.7 |

FDA regulation

Chocolate in various forms must conform with U.S. Standards of Identity. According to 21 CFR Part 163, chocolate liquor must contain not less than 50% nor more than 60% by weight of cacao fat. The following table summarizes the minimum requirements for differnet products:5

| Product | Liquor (%) | Milk solids (%) | Nutritive carb. sweeteners (%) | Fat (cocoa butter) (%) | emulsifiers (%) |

| Sweet chocolate | ≥ 15.0 | < 12.0 | Optional | Optional | 1.0% max |

| Bittersweet / Semisweet Chocolate | ≥ 35.0 | < 12.0 | Optional | Optional | 1.0% max |

| Milk chocolate | ≥ 10.0 | ≥ 12.0 | Optional | Optional | 1.0% max |

| White chocolate | – | ≥ 14.0 | ≤ 55.0 | ≥ 20.0 | 1.5% max |

References

- Karnjanolarn R, McCarthy KL. Rheology of different formulations of milk chocolate and the effect on coating thickness. Journal of Texture Studies 37.6 (2006): 668–80.

- Ačkar Đ, Škrabal S, Šubarić D, Babić J, Miličević B, Jozinović A. Rheological properties of milk chocolates as influenced by milk powder type, emulsifier, and cocoa butter equivalent additions. International Journal of Food Properties 18.7 (2014): 1568–574.

- Lambert, J.D. “Nutritional and Health Aspects of Chocolate.” Beckett’s Industrial Chocolate Manufacture and Use, 5th edition, John Wiley & Sons Ltd, 2017, pp. 521–531.

- Stauffer, C.E. “Chocolate and Confectionery Coatings.” Fats and Oils, Eagan Press Handbook Series, American Association of Cereal Chemists, Inc., 1996, pp. 91–100.

- U.S. Food and Drug Administration. CFR – Code of Federal Regulations Title 21 Part 163 – Cacao Products.” April 1, 2018, https://www.accessdata.fda.gov/scripts/cdrh/cfdocs/cfcfr/CFRSearch.cfm?CFRPart=163. Accessed 26 May 2019.