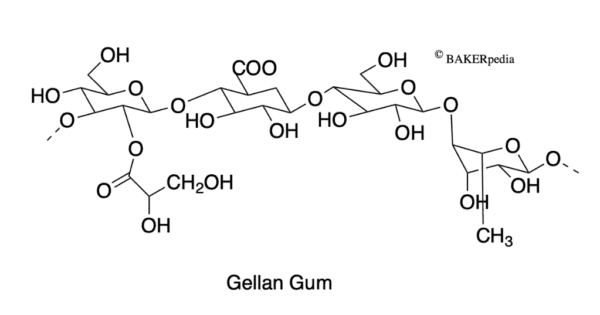

Chemical structure

Origin

Gellan gum is obtained from the aerobic fermentation of glucose by the Sphingomonas elodea bacteria, formerly known as Pseudomonas elodea. This species was first isolated from the Elodea plant.1,2 As a functional polysaccharide, this was first introduced by the Kelco Co.2

Function

Main attributes of gellan gum in baking include:1,2,3

- Gelling agent: produces an elastic and thermoreversible gel similar to gelatin.

- Thickener: mainly in jellies

- Binding agent: essential for vegan and gluten-free products.

- Stabilizing agent

- Flavor release agent: provides excellent flavor release in fruit jellies.

- Improves water holding capacity during processing and storage

- Reduces oil uptake and aids in formation of films or coat barriers.

Nutrition

Gellan gum is not absorbed by humans, and thus does not provide any caloric intake. As other polysaccharides, it can aid in bowel health and serum cholesterol reduction.4

Commercial production

Gellan gum is commercially manufactured through the following process:1,2

- Aerobic fermentation: Sphingomonas elodea bacteria are fed into a batch reactor containing a mixture of glucose, a nitrogen source and inorganic salts.

- Alkalinization: hot alkali at pH 10 and 80oC (176oF) is fed to the reactor for 10 min to obtain a low-acyl gellan gum.

- Precipitation: the gum is treated with hot propanol, and extracted.

- Clarification: fermentation liquor is filtered to obtain a bacteria debris free product.

The high-acyl form is obtained following the same process without the alkalinization step.12

For optimal manufacturing, the following parameters are critical:1,2

- Sterile conditions

- Aeration

- Agitation

- pH

- Temperature

Application

Vegan and gluten-free baked goods can benefit from gellan gum’s binding capacity and organic origin, thus making it a suitable partial substitute for eggs and wheat flour.1,2,3 In jellies and fillings it improves texture while providing excellent flavor release in comparison with other gums.1,2,3

Steps for incorporating this into formulations:1,2

- High-acyl gellan gum is heated up to 85 – 95 oC (185 – 203 oF) in a solution with less than 40% soluble solids, with water or milk as media and calcium citrate. Agitation is needed for gel formation.

- Low-acyl gellan gum is heated up to 75 oC (167oF) in water or milk as media, with calcium citrate. Agitation is needed for gel formation. Salt concentration should not exceed 1.3%.

Usage levels of gellan gum and impact on select formulations:

| Baked good | Usage level | Effect |

|---|---|---|

| Breading and butter | 0.01-3 % |

|

| Fried food (doughnuts) | 0.01-3 % |

|

| Jams and jellies | 0.01-3 % |

|

| Milk based fillings | 0.01-3 % |

|

Regulations

Gellan gum is generally recognized as safe by the FDA when used for its intended purpose following good manufacturing practices. The FDA establishes certain quality parameters for the Sphingomonas elodea bacteria used in its manufacturing.5

The EU Commission Regulation (EU) No 231/2012 recognizes this (E 418) as a permitted food additive. The FAO/WHO joint committee and the European Community Scientific Committee for Food have not specified an acceptable daily intake limit.4

References

- Nussinovitch, A, and Hirashima,M. Cooking innovations: Using hydrocolloids for thickening, gelling, and emulsification. CRC Press, 2013.

- King, R. D., ed. Food Biotechnology—1. Springer Science & Business Media, 2012.

- Kohajdová, Zlatica, and Jolana Karovičová. “Application of hydrocolloids as baking improvers.” Chemical papers 63.1 (2009): 26-38.

- Cho, S. S, ed. Handbook of dietary fiber. CRC Press, 2001.

- Food and Drug Administration (FDA). US Department of Health and Human Services. CFR Code of Federal Regulations Title 21, Part 172 Food Additives Permitted For Direct Addition To Food For Human Consumption, https://www.accessdata.fda.gov/scripts/cdrh/cfdocs/cfCFR/CFRSearch.cfm?fr=172.665#:~:text=The%20food%20additive%20gellan%20gum,by%20recovery%20with%20isopropyl%20alcohol. , Accessed 30 January 2021.