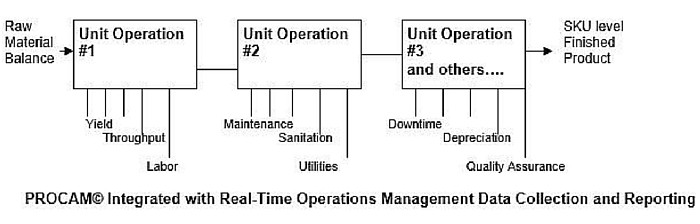

It is based on the following process engineering principles:

- Costs are based on Process Mass Balancing across a series of Unit Operations

- Costs are derived and allocated from the key elements of value added further process manufacturing such as:

- Processing line efficiencies, yields, throughput, machine efficiencies, etc.

- Ingredient and raw material costs

- Quality Assurance, Sanitation, and Research & Development

- Packaging and labeling

- Direct utilities

- Direct labor and productivity

- Fixed and allocated overhead

- Taxes and insurance, etc.

How was PROCAM developed?

PROCAM was jointly developed with a leading food industry executive from Kraft and PepsiCo with a Ph.D. in process engineering to address the need for an accurate activity based costing methodology that fits the unique requirements of the food and beverage processing industry. This methodology proved effective at identifying the fully allocated SKU cost of goods that was 10% less than the ‘historical’ allocated cost for a leading multibillion dollar food meat and poultry processor. This new, accurate, real-time cost information has provided this client with a clear picture of significantly larger profit margins that allow more competitive pricing with their leading customers – and still realize a larger profit margin to their company.

A leading big-5 consulting firm predicts the following minimum benefits. “ABC/M can help to reduce a company’s overall cost structure by as much as 3% to 5%…. An enhanced focus on higher margin and growth products and the pursuit of better markets can translate to a 5% to 15% increase in revenue” (Accenture, CFO Project Vol. 2, October 2003).

The PROCAM© process cost analysis methodology utilizes processing data that is both real-time (actual), historical, and comparative to industry best practices. PROCAM© allocates up to 20 line item costs commonly associated with food and beverage product processing at each Process Unit that composes the Production Line activities for each SKU item. The client’s processing data can also be cross-checked against industry norms specific to your processing segment. A few theoretical assumptions are used when required. SKU-based real-time PROCAM cost information can be used for:

- Data based Decision Making

- Identifying Financial Savings Opportunities

- Identifying Process Efficiency Improvement Opportunities

- Prioritizing Engineering and R&D Process Improvement and Development Efforts

Here’s an example of PROCAM Framework:

PROCAM© can now be integrated with FMSS Real-Time Operations Performance Management© data collection, analytics, and reporting information systems that are directly linked to corporate Key Performance Indicators and other OEE plant engineering metrics. FMSS has been the leader of real-time operations performance management analytics and reporting (RTOPM) within the food and beverage processing industry. This real-time cost analysis and reporting has enabled our clients to establish a competitive edge in unique niche areas such as Net Weight Scanable retail packaging.