Relevance and regulation

The first discovery of microbes and the role they play in food can be dated back to 1857, when Louis Pasteur showed that microbes were the cause of sour milk.3 In 1860 he discovered that heat could be used to destroy pathogenic microbes and developed the process known as pasteurization.

Because of the importance of his work, Pasteur is known as the founder of food microbiology and microbiological science.3

The Food Safety Modernization Act (FSMA) was signed into law in 2011 to emphasize the prevention of food safety hazards.4 Food companies are required to have food safety plans and to implement preventative controls to reduce the risks of potential hazards.

The FDA and USDA recommend implementing an HACCP system as part of a food safety program for food producers and retailers.5 An HACCP plan should include a microbial control program.

Types

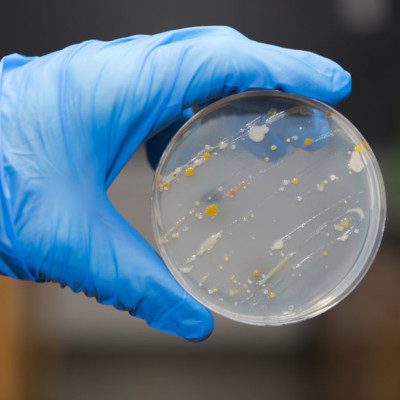

Conditions commonly found in bakeries and food process facilities are excellent for the growth of microorganisms. With plenty of food, moisture, and optimal temperatures, microbes will flourish.

Foodborne illness can be linked to the following microbes:6

- Bacteria

- Fungi

- Viruses

- Algae

- Eukaryotic parasites

Symptoms range from mild to life-threatening.

Components of a microbial control program

Risk assessment – The first step in establishing the microbial control program is to conduct a risk analysis, which identifies the types of microorganisms that will be a concern for the plant.1

Sampling – The sampling program identifies frequency, sources, and sample size of tests to be performed.1

Analytical testing – Testing procedures must be established using approved methods from authoritative sources such as the Association of Official Analytical Chemists (AOAC), Compendium of Microbiological Testing, and FDA’s Bacteriological Analytical Methods.1

Lab security – A microbiological testing lab contains many materials that pose a risk to product and must be managed carefully.2 Safety protocols should ensure that access to the lab is limited to authorized personnel.

Validation (check sample) – Scientific validation of a microbial kill step will ensure product safety and regulatory compliance. The check sample program is based on sharing a sample among multiple technicians (in-house and third-party) and comparing results to identify non-compliance with procedures and to determine corrective actions.2

Education and training – Standard operating procedures (SOPs) should be developed, and all personnel must undergo training for the microbial control program.1

References

- AIB International. “Food Safety and Sanitation.” Food Safety and Sanitation Distance Learning Course. Chapter 19.

- AIB International. “Microbial Control Program.” The AIB GMP and Prerequisite Guide. Section 6, Chapter 8.

- Oberg, C. “Micro 3835: History of Food Microbiology.” Weber State University, Department of Microbiology, www. faculty.weber.edu/coberg/class/3853/3853%20HistoryofFood.htm.

- U.S. Food and Drug Administration. “Background on the FDA Food Safety Modernization Act (FSMA).” News & Events, 17 Nov. 2017. https://www.fda.gov/NewsEvents/PublicHealthFocus/ucm239907.htm

- U.S. Food and Drug Administration. “HACCP Principles & Application Guidelines.” Guidance & Regulation, 14 Aug. 1997.

- Oberg, C. “Micro 3835: Foodborne Disease.” Weber State University, Department of Microbiology, https://faculty.weber.edu/coberg/class/3853/3853%20Foodborne%20Diseases.htm