How does it work?

In the cereal processing industry, the most commonly applied method for testing moisture in flours involves the use of an air oven (AACCI Approved Method 44–15.02). This method determines moisture content as loss in weight of a sample when heated under specified drying conditions. This method is applicable to flour, semolina, bread and all kinds of grain-based products.2

The AACCI Method 44–15 consists of the following steps:3

- Weighing and grinding a small sample of flour (2–3 grams) and placing it into a dish

- Heating sample at 130°C (266°F) in an air oven for 60 minutes

- Cooling sample to room temperature

- Weighing residue (dried sample)

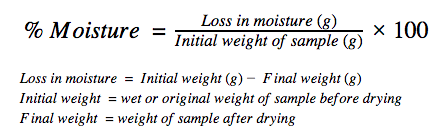

- Determining moisture content by comparing the weight of the sample before and after heating. The moisture (water) content is calculated by the following formula:3,4,5

The amount of weight loss is the moisture content. Moisture content results are expressed as a percentage. An example of a wheat moisture content is 12%.

Alternative methods for determining moisture content in flours include near-infrared reflectance analysis (NIR). This instrumental high-tech equipment is used for online and rapid determination of moisture as well as protein and ash. In such cases, the instruments need to be properly calibrated.1

Application

Moisture in flour is very important for bakers and millers. The following are some of the reasons:

- Moisture content of flour is a shelf-life and stability indicator. Low moisture levels inactivate enzymatic activity and microbial growth (fungal and bacterial).

- Moisture content is a means for controlling pests.

- Content of dry solids (of real value for processors). The lower the moisture, the higher the dry solids content (protein, starch, fat, sugars, ash).

- The higher the water content, the lower the value of the flour as less solids can be used to produce value-added products.

- It may affect processing and handling conditions. High moisture flours can lead to production problems because wetter flours agglomerate more readily, causing hoppers and conveyors to block when flour clumps, resulting in laborious cleaning efforts and downtimes.4

- Some flours destined for cake mixes are usually shipped and delivered at baking plants with 10% moisture to improve the quality and shelf life of the mix. Such specifications require pneumatic flash dryers to be used at the mill.1

The actual or measured moisture level in a flour is used to adjust analytical calculations and laboratory procedures. For example, in the solvent retention capacity (SRC), amylograph and farinograph test, and proximal analysis reports (e.g., protein, ash), the moisture content of flour must be first brought to 14%, the standard conversion factor for tests in which the results are affected by moisture content.3

References

- Posner, E.S. “Flour Handling and Blending.” Wheat Flour Milling, 2nd printing, AACC International, Inc., 2011, pp. 291–327.

- AACC International. Approved Methods of Analysis, 11th Ed. Method 44-15.02. Moisture—Air-Oven Methods. Approved November 3, 1999. AACC International, St. Paul, MN, U.S.A.

- Wheat Marketing Center, Inc. “Wheat and Flour Tests: Moisture Content.” Wheat and Flour Testing Methods: A Guide to Understanding Wheat and Flour Quality, 2004, p. 11.

- Finnie, S., and Atwell, W.A. “Wheat and Flour Testing.” Wheat Flour, 2nd edition, AACC International, Inc., 2016, pp. 60–61.

- AACC International. Approved Methods of Analysis, 11th Ed. Method 44-01.01. Calculation of Percent Moisture. Approved November 3, 1999. AACC International, St. Paul, MN, U.S.A.