Origin

Preferments represent the art, science and craft of baking. These are at least as old as bread itself. Primitive dough leavening involves letting the flour and water be colonized by yeast and bacteria naturally present in the air. The accompanying fermentation reactions are responsible for the mellowing and acidification of dough that ultimately modify the sensory characteristics of baked goods.

How does it work?

In a preferment, a portion of the total formula flour is fermented prior to mixing with dough ingredients. The pre-fermented mixture contains flour, water and yeast/microorganisms. Depending on the water content, it can be liquid (pumpable) or plastic.

They can be made using:

- Baker’s yeast, any commercial form (compressed, cream, active dry or instant)

- Wild or natural yeast (airborne) – sourdough

- Wild lactic acid bacteria (airborne) – sourdough

By initiating biochemical processes, preferments can:

- Develop gluten-forming proteins in flour

- Improve flour hydration

- Produce flavors and aromas

- Improve the finished product shelf-life through pH modification

- Improve the finished product texture

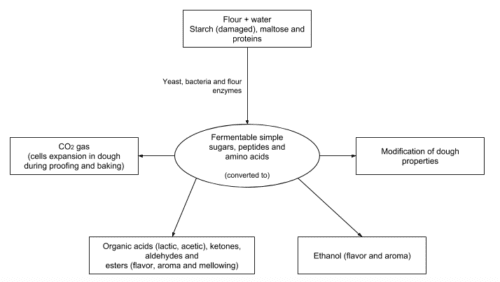

When a flour-water mixture encounters microorganisms, a series of fermentation reactions ensues that ultimately produce products to improve the quality of baked goods.

The following diagram summarizes the changes that occur within a preferment:

Application

Preferments need to be properly controlled. Variables that need careful attention are:

- Fermentation time

- Temperature

- Relative humidity of fermentation environment (cabinet, room, proof box or retarder)

- pH

- Total titratable acidity (TTA)

- Microbial count (some processes are controlled by the population of microorganisms)

Specifications for cereal flours used in preferments include:

- Class of wheat with optimum performance: Hard red spring (HRS), Hard red winter (HRW), Hard white (HW)

- Strong flour with high protein content (>13.0%) requires a long fermentation time (more than 10 hours)

- Sufficient amylase activity to support long fermentations without added sugar

- Intermediate to high level of damaged starch is preferred

- Flour with low enzymatic activity should be supplemented with diastatic malt

Advantages and disadvantages

| Advantages | Disadvantages |

|

|

References

- Suas, M. “Bread and Pastry: A Historical Perspective and Current Opportunities” Advanced Bread and Pastry: A Professional Approach, Delmar Cengage Learning, 2009, pp. 5–19.

- Cauvain, S.P. “Sour Dough Technology.” Encyclopedia of Food Grains, 2nd edition, Volume 3 Grain-Based Products and their Processing, Academic Press, Elsevier Ltd., 2016, pp. 25–28.