Origin

Rheology was the name given to the discipline of a society, in 1929, that was engaged in the study of how materials deform in response to forces. Its goal is to provide quantitative parameters that define how a material will deform as a function of force, time and spatial orientation.2

“Everything flows” – Heraclitus. However, this flow depends on force, direction and duration.2

How rheology works

In baking and cereal science, rheology is of particular interest. Dough is a viscoelastic material which behaves as both a liquid and a solid. It exhibits a viscous (fluid-like) and an elastic (solid-like) behavior when a force is applied to it. Gluten-forming proteins and polysaccharides, once hydrated and thoroughly mixed, are responsible for this viscoelastic nature.

Rheological properties of dough and batter (also known as handling properties):

- Elasticity: the degree to which a dough piece will attempt to regain its original shape after a deforming force has been removed. The dough should have a minimum of elasticity to avoid misshaping caused by “spring-back” after sheeting and moulding.

- Extensibility: ability of dough to stretch or deform. Deforming forces include sheeting and moulding pressures as well as gas pressure from yeast fermentation. Dough should have enough extensibility (and minimal elasticity) to yield significant dough expansion during proofing and baking.

- Resistance to deformation: this concept is equivalent to “dough softness.” Dough should have as little resistance to deformation as possible. This translates to ease of shape change during sheeting and moulding to avoid damaging the somewhat unstable gas cells incorporated during mixing.

- Viscosity: resistance of liquid products, such as batters, to movement or shear forces.3

Application

Dough rheology is studied because it is related to breadmaking and quality of final product. Two types of rheological methods are used to assess rheological properties of doughs and batters, these are:1,4

- Fundamental

- Tube type (Capillary flow)

- Glass capillary

- High pressure capillary

- Pipe

- Rotational type

- Parallel plate

- Concentric cylinder

- Cone and plate

- Mixer

- Tube type (Capillary flow)

- Empirical

The following are empirical methods used in the baking and milling industry. These tests measure rheological properties of dough and batter under test conditions, trying to simulate as much as possible the processing conditions found in commercial plants:

| Testing Method | Predominant Force Evaluated | Details |

| Farinograph | Shear stress/forces | Test: recording dough mixer.

Principle of operation: measure and record the resistance over time of a flour/water dough against mixing blades or pins operating at a specific speed (rpm) and specific temperature(s). Property measured: resistance to deformation as motor torque in dimensionless values (e.g. Brabender Units). |

| Extensograph | Tensile stress (uniaxial extension) | Principle of operation: measures and records the extensibility and resistance to extension of a fully mixed, relaxed flour/water dough. Deforming forces are applied via a hook that moves at a constant rate until the dough ruptures.

Property measured: stress / strain relationships. Resistance to deformation (tensile stress) in Pa or N/m2, or dimensionless values (e.g. Brabender Units). |

| Alveograph | Tensile stress (biaxial extension) | Principle of operation: measures and records the resistance to deformation of a flour/water dough. Deformation forces responsible for dough expansion are applied by blowing (inflating) the dough piece into a bubble until it ruptures. |

| Mixolab | Shear stress/forces | Principle of operation: measures and records the resistance to deformation over time of a flour/water dough while it is subjected to variable shear forces and heating and cooling cycles.

Property measured: resistance to deformation as motor torque in N x m. |

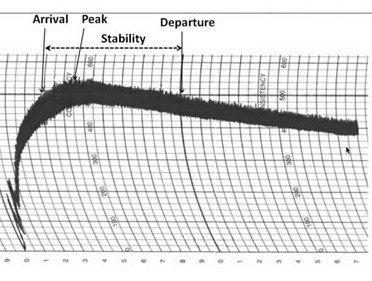

| Viscometer

Viscoamylograph |

Shear stress/forces | Principle of operation: measures and records the resistance to deformation over time of a flour/water slurry or batter while it is subjected to heating and cooling cycles.

Property measured: resistance to deformation as viscosity in Pa x S, centipoise (cP), or dimensionless values. |

References

- Steffe, J.F. “Introduction to Rheology.” Rheological Methods in Food Process Engineering, 2nd Edition, Freeman Press, 1996, pp. 1–93.

- Janmey, Paul A., and Manfred Schliwa. “Rheology.” Current Biology 18.15 (2008): R639-641.

- Singh, R.P., and Heldman, D.R. “Fluid Flow in Food Processing.” Introduction to Food Engineering, 4th Edition, Academic Press, Elsevier Inc., 2009, pp. 65–81.

- Rao M.A. “Rheological Properties of Fluid Foods.” Engineering Properties of Foods, 4th Edition, CRC Press, Taylor & Francis Group, LLC.,

- 2014, pp. 121–177.