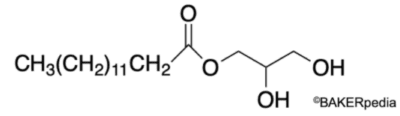

Chemical structure

Origin

The development of emulsifiers evolved in parallel to shortenings for baking purposes and the advancement in lipid chemistry.1

Succinylated monoglycerides are obtained from fats and oils through a succinylation reaction. In the US alone around 500,000 pounds of emulsifiers are used in the food industry, with the baking industry accounting for about half of the emulsifiers market.1

Function

Succinylated monoglycerides have wide variety of functions in baked goods, some of which are:1

- Dough conditioning: increases mixing and dough mechanical stress tolerance

- Dough strengthener: improves gas retention and loaf volume

- Crumb softening: retards crumb hardening by decreasing free amylose

- Prevents staling: due to the retardation of starch retrogradation

- Blending: assist in blending and emulsification of ingredients

- Enhance shortening properties

- Moisture retention: shelf life extension

- Improves quality: aids the quality of baked goods production and compensates for variations in raw materials

- Increased aeration

Nutrition

Emulsifiers such as succinylated monoglycerides can significantly reduce non-waxy starch digestibility, thus reducing its glycemic index.3

Commercial production

Succinylated monoglycerides are manufactured through the reaction of a distilled monoglyceride with succinic anhydride at a temperature range of 80-180 °C (175-350°F).3 At temperatures below 95°C (<200°F) an alkaline catalyst may be required to accelerate the reaction. However, at higher temperatures no catalyst is required.3

Succinylated monoglycerides must meet the following specifications according to the FDA:

| Specification | Value |

| Succinic acid | 14.8 – 25.6 % |

| Melting point | 50 – 60 °C (122 – 140 °F) |

| Acid number | 70 – 120 |

Application

A wide range of baked goods include succinylated monoglycerides. This emulsifier has an HLB range from 5-7, giving it a lipophilic nature. It is best used after dissolving it in the shortening or lipid phase of the baked good before mixing with the rest of the ingredients.

The following table shows usage limits, benefits and drawbacks of using succinylated monoglycerides in baked goods:1

| Baked good | Limit | Benefits | Drawback |

| Yeast-raised products | 0.5% |

|

Less effective volume improver than other monoglycerides |

| Cakes | 0.5% |

|

Less common than PGME* and SSL** |

| Cookies and crackers | 0.5% |

|

Provides less spread than SSL |

| Shortening | 3% |

|

– |

*PGME: propylene glycol monoester

** SSL: sodium stearoyl lactylate

Regulations

Succinylated monoglycerides can be safely used in foods providing they meet the FDA specifications. They can only be used in shortening as an emulsifier (≤ 3%) and in bread baking (≤ 0.5%) as a dough conditioner.4

They are not currently approved in the European Union, however they have an assigned E number, E 472g.5

References

- Hasenhuettl, G. L., and Hartel, R. W,. Food emulsifiers and their applications. Vol. 40. No. 6. 3 rd ed.,Springer, 2019.

- Guraya, Harmeet S., Ranjit S. Kadan, and Elaine T. Champagne. “Effect of rice starch‐lipid complexes on in vitro digestibility, complexing index, and viscosity.” Cereal Chemistry 74.5 (1997): 561-565.

- O’Brien, R.D. Fats and oils: formulating and processing for applications. 2 nd ed., CRC press, 2004.

- Food and Drug Administration (FDA). US Department of Health and Human Services. CFR Code of Federal Regulations Title 21, Part 172 Food Additives Permitted For Direct Addition To Food For Human Consumption,https://www.accessdata.fda.gov/scripts/cdrh/cfdocs/cfcfr/CFRSearch.cfm?fr=172.830, Accessed 6 August 2020.

- European Commission. “FOODS SYSTEM”. Webgate.Ec.Europa.Eu, 2020, https://webgate.ec.europa.eu/foods_system/main/index.cfm . Accessed 7 Aug 2020.