Origin

Water brews became popular when wholesale bakeries started to expand and invest in high-speed and technical production lines. Cutting labor costs has always been a key profitability factor in the baking industry. With the advent and modernization of continuous mix dough systems, the need for a reliable supply of dough became an essential competitive advantage and bakeries soon started to use cream yeast for the production of high-demand products such as pan bread and hamburger buns.

How does a water brew work?

Since no flour is added in the pre-fermentation stage, all the flour is added at dough mixing. A water brew consists of:

- Water (10%)

- Yeast (3.5%, usually cream)

- Sugar (3.0%). Since no flour is added in the brew or broth, sucrose, glucose, or high fructose corn syrup must be added to supply enough food for the yeast for proper fermentation.

- Buffering agents (0.1–0.25%). Calcium salts of calcium carbonate help to control pH drop.

- Salt (optional ingredient)

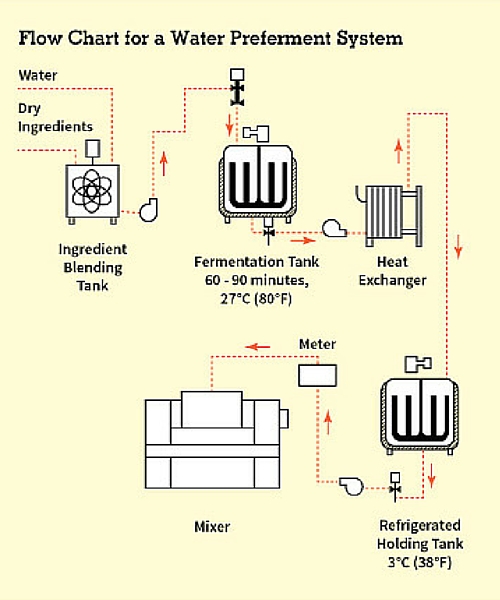

The process used to obtain a water brew is:

- Scaling of brew ingredients

- Blending to incorporate ingredients

- Fermentation with an agitation 27°C (80°F) for 60–90 minutes

- Chilling through heat exchanger. At a temperature of 4–7°C (39–45°F), this step slows or stops the fermentation rate

- Holding in a vessel for 8 hours at 3–5°C (37–41°F) until it is ready for use in dough mixing

Since yeast cells greatly benefit from the rich water medium and have instant access to fermentable sugars, water brews are fermented for a shorter time than brews containing flour. After fermentation, the final broth will be more acidic than pre-ferments made with flour.

Application

A water brew is a beneficial process in terms of production flexibility because the same ferment or intermediate product can be used for multiple batches of dough, either with many of the multiple types of doughs or different varieties. It can also be used to supply continuous mix dough systems.

The advantages and disadvantages of a process being supplied by a water brew are:2

| Advantages | Disadvantages |

|

|

Food safety and quality considerations

- Equipment involved in processing and handling liquid or water brews should allow for maintenance, inspection and cleaning activities to be performed easily and properly to reduce downtime.

- Stainless steel blending, fermentation and holding tanks, piping, heat exchangers (tubular or plate), pumps, can be all cleaned-in-place (CIP) by using high-pressure spraying/jetting and turbulent flow procedures. The frequency of cleaning tasks depends on the nature of the process and sanitation standards established in the bakery.

- The control of pH and TTA (total titratable acidity) during liquid fermentation is vital for the brew to develop the correct flavors and characteristics. Post-ferment target value for pH is 4.4 to 3.8, and for TTA is 10 to 12.

References

- Moore, T.R. “Breads” Encyclopedia of Food Grains, 2nd ed., vol. 3, Elsevier Ltd., 2016, pp. 8–12.

- Carson, L. “Water Preferment” Dough Systems. A Guide On Formulating Sponge and Dough, Preferments and Straight Dough Systems, BAKERpedia, LLC, 2017, pp. 16–19.

- Cauvain, S.P. “Speciality Fermented Goods.” Technology of Breadmaking, 3rd edition, Springer International Publishing Switzerland, 2015, pp. 253–258.