Origin

Thousands of years ago, people in ancient civilizations recovered top-fermenting yeasts of the genus Saccharomyces from the production of fermented beverages such as beer, and used them as leavening agents in primitive breads.

Baker’s yeast, as a commercially manufactured microbial cell for the production of bread doughs, dates from the late 1800s. In 1868, Fleischmann founded the compressed baker’s yeast industry in the United States.¹

Function

Compressed yeast is perhaps the second most important ingredient in bread making. Similar to other yeast forms, its major role is to convert fermentable carbohydrates into CO2 gas and ethanol. The gas and other minor metabolites, such as organic acids, provide the leavening effect that produces a light loaf of bread.

Compressed yeast performs the following functions in yeast-leavened baked goods:²

- Dough rising

- Texture improvement

- Acidification of dough

- Flavor enhancement

- Modification of rheological properties of dough

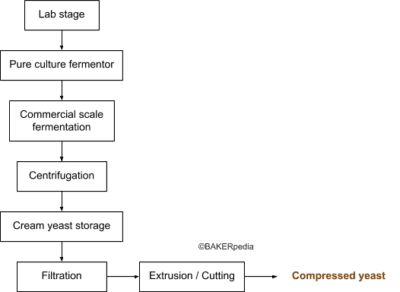

Commercial production

Nutrition

Yeast is recognized as an excellent source of proteins, B vitamins, fiber, and many other micronutrients.¹

Application

Compressed yeast is mostly sold in 15-20 Kg (33–44 lb) plastic bags. Upon arrival at the bakery, compressed yeast is stored in dedicated rooms under refrigeration temperatures.

Considerations when using compressed yeast:

- Gassing power or vitality: gassing power is an essential parameter in any yeast spec sheet. It is defined as the amount (in mL) of CO2 gas produced under lab conditions

- Cell viability: percentage of live (viable) cells within a yeast population

- Moisture and total solids content

- Invertase activity (1 µmole of reducing sugar released in 5 min per mg of yeast dry matter)

- pH and phosphorus content

- Vitality after 7 days of refrigeration storage

- Glutathione content

- Refrigerated storage records

- Production date and stock levels (it is always better to use compressed yeast as fresh as possible)

- Absence of off-flavors and off-odors

Unlike active dry yeast (ADY), compressed yeast does not require an activation or hydration step prior to usage. It is common to see compressed yeast being replaced by cream yeast, although this situation may only be feasible in high-speed bakeries which need to meet world class efficiency levels.

The following table summarizes some key parameters of fresh yeast:

| Yeast form | Conversion factor relative to other yeast forms | % Moisture | % Solids |

| Compressed | 1.0 | 70 | 30 |

The following table summarizes the advantages and disadvantages of compressed yeast:

| Advantages | Disadvantages |

|

|

FDA regulation

There are no limitations regarding the use of yeast in the production of food products. Any type of yeast must conform to microbiological and physicochemical specifications established by good manufacturing practices.

References

- Athnasios, A.K., and Quantz, M. “Yeasts.” Ullmann’s Food and Feed, Part III: Bulk Food Component, Wiley-VCH Verlag GmbH & Co. KGaA, 2017, pp. 1013–1026.

- Poitrenaud, B. “Yeast.” Handbook of Food Science, Technology, and Engineering, Part F. Fermentation Principles, CRC Press, Taylor & Francis Group, LLC, 2006, pp. 1–18.