Origin

Pasteurization was invented by French chemist and microbiologist Louis Pasteur (1822–1895). He demonstrated that fermentation was caused by the growth of microbes and not by spontaneous exposure to ambient air.

In his trials, Pasteur heated a liquid food in long, swan-necked jars to sterilize it. The jars were filtered so that only air and not dust or other particles were present. He observed that nothing grew in the liquid sample unless the flasks were broken open. He then concluded that the living organisms that grew came from outside as air-borne spores, rather than being spontaneously generated within the liquid food.

After his experiments, he was able to prove that the growth and metabolic activity of microorganisms were responsible for spoiling products such as beer, wine, and milk. He invented a process in which milk was heated to kill most bacteria and molds already present. This process was soon afterward known as pasteurisation.2

How does pasteurization work?

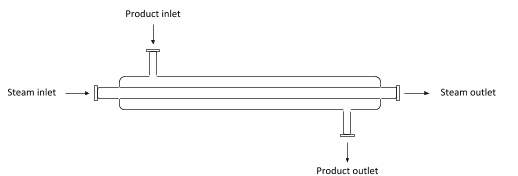

Pasteurization is carried out in heat exchangers operating in batch with a total load contained in a vessel, or in continuous mode in a basis of liters per second running in pipework. A heat exchanger is a piece of equipment designed to transfer thermal energy (via convection and conduction) from one fluid to another separated by a heat conducting partition, such as a metal wall.

According to thermodynamic laws, heating involves the transfer of heat from a hot point to a cold point. Types of heat exchanger include plate, tubular, shell and tube, among others.

As a result, for pasteurization to occur, a hot liquid (transfer fluid, usually saturated steam) and a cold liquid (the product to be processed) are needed.

Schematic representation of a continuous pasteurizer.

There are various pasteurization methods or technologies:3

- Low-temperature, long-time. This process involves heating products to 63°C (145°F) and holding them at that temperature for at least 30 minutes. In this case, the pasteurization does not achieve complete destruction of all microbes i.e., sterilization.

- High temperature, short time (HTST). Method used to pasteurize milk and dairy products. This process usually uses a minimum of 72–75°C (161–167°F) and a holding time of a minimum of 15–20 seconds.

- Ultrapasteurization or ultra-high temperature processing (UHT). This method requires a much higher temperature of 85°C (185°F) and a shorter holding time. Combinations of 123–145°C (253–293°F) for <1–5 seconds are usually seen in the industry. This process requires both the product and packaging to be sterile prior to filling.4

- In‐container sterilisation. In this case, the thermal treatment is accomplished after the product is placed in the container or package.

Application

Pasteurization is widely used in the food industry. The following are a few examples:

- Stabilization of incoming raw materials or ingredients, e.g., liquid milk. This allows these materials to be stored and used in the production of value-added products. Milk bread is produced with liquid milk as the only moistening agent to comply with U.S. Standards of Identity.

- Production of dry milk solids, dairy blends, and cereal-dairy blends (milk replacers) used in the production of yeast-leavened bakery products. High-heat dry milk is preheated to 85°–88°C (185°–190°F) for 30 minutes to denature (inactivate) the milk proteins (globulins) responsible for generating detrimental effects on the stability of gas bubbles and causing the cake and bread dough to become too extensible and sticky.5

- No-shell egg products intended for used in baking plants must be pasteurized according to USDA laws. The conditions for pasteurization must be carefully controlled to assure destruction of pathogenic organisms but not damage the desired functional properties of the proteins in egg.6

- Processing and shelf-life extension of cream, a fat-rich ingredient used in bakery formulations such as cakes and pastries. FDA provides specific guidelines about the pasteurization of this dairy product.

- Despite not being known as such, the baking process is indeed a pasteurization step. In this case, apart from its effect on product structure and texture, it reduces the microbial count, extending shelf-life of bakery products.

References

- “PASTEURIZED MILK..” JAMA XLII.21 (1904): 1360-1361.

- Featherstone, S. “Introduction.” A Complete Course in Canning and Related Processes, 14th edition, vol. 1, Woodhead Publishing (Elsevier Ltd.), 2015, pp. 4–6.

- Deeth, H.C. “Heat Treatments of Milk – Thermisation and Pasteurisation.” High Temperature Processing of Milk and Milk Products, John Wiley & Sons Ltd, 2017, pp. 15–34.

- Lewis, M. J., and Jun, S. “Thermal Processing.” Food Processing Handbook, 2nd edition, vol. 1, Wiley-VCH Verlag & Co., 2012, pp. 31–40.

- Cauvain S.P. “Raw Materials.” Baking Problems Solved, 2nd edition, Woodhead Publishing (Elsevier Ltd.), 2017, p. 101.

- Manley, D. “Milk Products and Egg as Biscuit Ingredients.” Manley’s Technology of Biscuits, Crackers and Cookies, Woodhead Publishing Limited, 2011, pp. 191–199.