Origin

Pentosans are naturally found in the cellulose of plants and in humus.

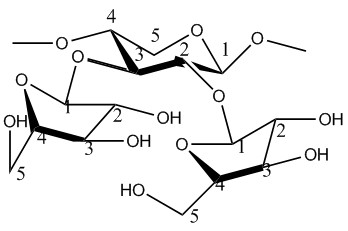

Arabinoxylan structure. D-xylopyranosyl residue substituted on C(O)-2 and C(O)-3 with L-arabinofuranosyl residues.3

Nutrition1,2

Here are a few grains and flours that contain pentosans:

- Whole wheat:

- 0.9 soluble pentosans

- 2.45 enzyme-extractable pentosans

- 8.95%total pentosans

- Wheat flour:

- 0.7-0.83% soluble pentosans

- 1.66-1.86% enzyme-extractable pentosans

- 1.5-2.12%total pentosans

- Wheat bran:

- 0.28 water soluble pentosans

- 21.30% total pentosans

- Rye:

- 2.08 water soluble pentosans

- 5.41% total pentosans

- Rye flour:

- 2.40 water soluble pentosans

- 3.15% total pentosans

- Rye bran:

- 1.60 water soluble pentosans

- 14.86% water total pentosans

There is water extractable pentosan (WEP) and water unextractable pentosan (WUP). The difference between WEP and WUP is the degree of branching. WUP is cross-linked in the cell wall structure. WUP, insoluble dietary fiber, reduces transit time and increases fecal bulk, frequency of defecation, and binding and excretion of carcinogens. WEP, soluble dietary fiber, is more readily fermentable in the colon than insoluble dietary fiber. It causes a shift to lower colonic pH and increases the number and changes the profile of intestinal micro-organisms.

Dietary fiber fermentation results in the production of short-chain fatty acids favoring bowel health. Soluble dietary fiber in particular lowers both cholesterol and glucose absorption in the small intestine and postprandial blood insulin levels. Attenuation of blood cholesterol is related to reduce risk of type 2 diabetes.

Function

Pentosan has a significant effect on wheat functionality.

WEP forms highly viscous solutions when dissolved in water. The solution viscosity is quite high when compared with those of other non-starch polysaccharides such as gum Arabic, dextran or pullulan.3 WEP increases the viscosity of the dough aqueous phase, therefore, increasing the stability of the liquid films and dough foam structure. The increased stability can prolong oven rise and prevent early coalescence of gas cells. This results in higher loaf volume and a finer homogeneous breadcrumb. It is also possible that WEP, because of its high molecular weight, forms a secondary, weaker network enforcing the gluten network.3

In contrast to WEP, WUP destabilizes the dough structure. It is present in the discrete cell wall fragments that can form physical barriers for the gluten network during dough development. During fermentation, it can form intrusions in the gas cells. It also absorbs a large amount of water, which is consequently not available for gluten development and film formation. WUP has strong tendency to absorb water and swell, being reported to be able to hold 6 to 10 times its weight in water.3 As such, it lowers the stability of the gluten network. Lower loaf volumes with coarser crumb and higher initial crumb firmness are obtained.3

Both WEP and WUP can retard the staling rate of bread due to their high water holding capacity.4

Application

Pentosans are often added in breadmaking as natural improvers, dietary fiber fortification, or for economic benefits. The source, quality and amount of pentosans to add are important for bread quality enhancement. Research shows when WEP and WUP from wheat and WEP from rye are added in concentrations of 0.5%, 1.0%, 1.5% and 2.0% to flour samples,5 all three pentosans markedly increased the water absorption and loaf volume, and retarded bread staling. The structure of WUP may be modified during the extraction process. In other studies, 0.8% AX was added to wheat bread flour, with 2.5% flour removal. The AX fortified bread maintained similar weight, volume, height and firmness as standard white bread.6

To solve the problem caused by WUP, endoxylanases with a specificity towards water unextractable arabinoxylan (WU-AX) can be used. They catalyse the conversion of detrimental WU-AX to high molecular weight enzyme-solubilised AX with beneficial functionality in bread-making. Enzyme dosage is important. Optimal dosage could improve bread loaf volume, crumb structure and crumb softness, increase fermentation stability and resistance to mechanical stress and oven rise.3 Yet extensive dosage leads to extensive degradation of WU-AX. This leads to the decrease in water holding capacity of dough. Slack doughs and dough stickiness after mixing may occur.3

References

- Hashimoto, S., M. D. Shogren, and Y. Pomeranz. “Cereal Pentosans: Their Estimation and Significance. I. Pentosans in Wheat and Milled Wheat Products.” Cereal Chemistry 64.1 (1987): 30-34.

- Fengler, Adam I., and Ronald R. Marquardt. “Cereal Chemistry.” Water-soluble Pentosans from Rye: I. Isolation, Partial Purification, and Characterization 65.4 (1988): 291-97.3.

- Courtin, C.m., and J.a. Delcour. “Arabinoxylans and Endoxylanases in Wheat Flour Bread-making.”Journal of Cereal Science 35.3 (2002): 225-43.

- Gobbetti, M., M. De Angelis, P. Arnaut, P. Tossut, A. Corsetti, and P. Lavermicocca. “Added Pentosans in Breadmaking: Fermentations of Derived Pentoses by Sourdough Lactic Acid Bacteria.” Food Microbiology 16.4 (1999): 409-18.

- Denli, Emine, and R. Ercan. “Effect of Added Pentosans Isolated from Wheat and Rye Grain on Some Properties of Bread.” European Food Research and Technology 212.3 (2001): 374-76.

- Koegelenberg, Danika, and Annie F.a. Chimphango. “Effects of Wheat-bran Arabinoxylan as Partial Flour Replacer on Bread Properties.” Food Chemistry 221 (2017): 1606-613.